10 Ways Clear and Accurate Assembly Work Instructions Benefit the Automobile Manufacturing Company

The Starting Point for Quality Manufacturing Assembly Instructions is Planning

Thorough planning is the precursor to creating quality manufacturing work instructions. With thousands of parts and many subsystems, this is particularly important for automobile manufacturing.

Each assembly step needs to be planned considering several factors. What is the best assembly process? For an automobile, there might be thousands of steps, so planning the proper order is critical, as it will be repeated over and over during production. Proper planning will be heavily rewarded once production starts. Planning and subsequent work instructions are crucial for maintaining consistency, ensuring quality control, and improving operational efficiency in automobile assembly.

1. Consistency in Operations:

Clear assembly line work instructions guarantee that all assembly line workers adhere to the same guidelines, promoting consistency in the manufacturing processes. For instance, precise instructions for installing automotive components, such as engines and transmissions, ensure the uniform assembly of vehicles.

Clear assembly line work instructions guarantee that all assembly line workers adhere to the same guidelines, promoting consistency in the manufacturing processes. For instance, precise instructions for installing automotive components, such as engines and transmissions, ensure the uniform assembly of vehicles.

2. Quality Control:

Unambiguous assembly instructions enable better control over the quality of automobiles. Clear instructions for assembling safety components like airbags and braking systems guarantee high-quality and reliable performance in every vehicle produced.

3. Reduced Errors and Rework:

Ambiguities in assembly instructions can lead to mistakes and errors, necessitating rework. Clear instructions minimize these errors. In automobile manufacturing, explicit guidelines for assembling electronic control units can prevent defects and subsequent rework on the production line.

Ambiguities in assembly instructions can lead to mistakes and errors, necessitating rework. Clear instructions minimize these errors. In automobile manufacturing, explicit guidelines for assembling electronic control units can prevent defects and subsequent rework on the production line.

4. Efficiency Improvement:

Well-defined assembly instructions streamline the automobile manufacturing process, making it more efficient. Clear instructions for assembling chassis components such as suspension systems and steering mechanisms significantly reduce production time and increase overall efficiency in automotive assembly plants.

5. Training and Onboarding:

Clear assembly line instructions facilitate the training of new assembly line workers and the onboarding process. For example, detailed instructions for assembling complex systems like hybrid or electric vehicle powertrains help new employees quickly adapt to the dynamic and evolving automotive manufacturing environment.

6. Standardization:

Unambiguous work instructions contribute to standardizing automobile assembly processes. In the production of mass-market vehicles, standardized assembly instructions for body assembly and welding processes ensure structural integrity uniformity, and compliance with safety standards.

7. Risk Mitigation:

Ambiguous assembly instructions can lead to safety hazards. Clear and precise instructions reduce the likelihood of accidents. In automobile manufacturing, well-defined assembly instructions for handling hazardous materials and assembling high-voltage systems contribute to a safer work environment and regulatory compliance.

Ambiguous assembly instructions can lead to safety hazards. Clear and precise instructions reduce the likelihood of accidents. In automobile manufacturing, well-defined assembly instructions for handling hazardous materials and assembling high-voltage systems contribute to a safer work environment and regulatory compliance.

8. Communication and Collaboration:

Clear assembly instructions are essential for effective communication and collaboration between teams and departments in automobile manufacturing. They facilitate the understanding of design intent, resulting in improved quality and performance of vehicles.

9. Regulatory Compliance

This is another crucial aspect of automobile manufacturing. Clear assembly instructions are key in ensuring that manufacturing processes adhere to safety and emissions regulations. For example, detailed instructions for assembling emission control systems help meet environmental standards.

This is another crucial aspect of automobile manufacturing. Clear assembly instructions are key in ensuring that manufacturing processes adhere to safety and emissions regulations. For example, detailed instructions for assembling emission control systems help meet environmental standards.

10. Customer Satisfaction:

Producing high-quality automobiles consistently, with clear adherence to specifications, is crucial for customer satisfaction. Clear assembly instructions for advanced driver assistance systems, for instance, contribute to the production of vehicles that meet or exceed consumer expectations in terms of safety and convenience.

Producing high-quality automobiles consistently, with clear adherence to specifications, is crucial for customer satisfaction. Clear assembly instructions for advanced driver assistance systems, for instance, contribute to the production of vehicles that meet or exceed consumer expectations in terms of safety and convenience.

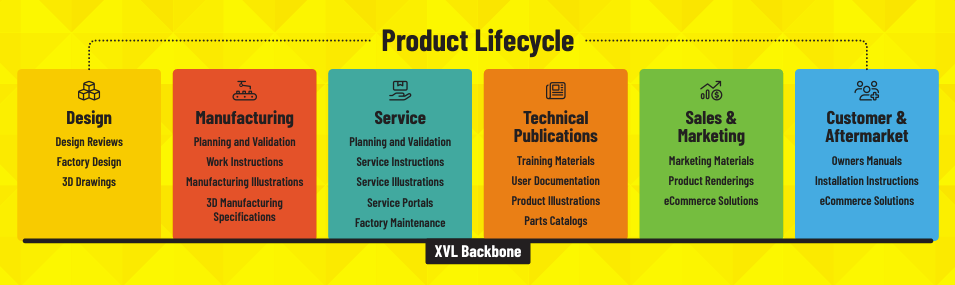

How Can XVL Benefit these Endeavors?

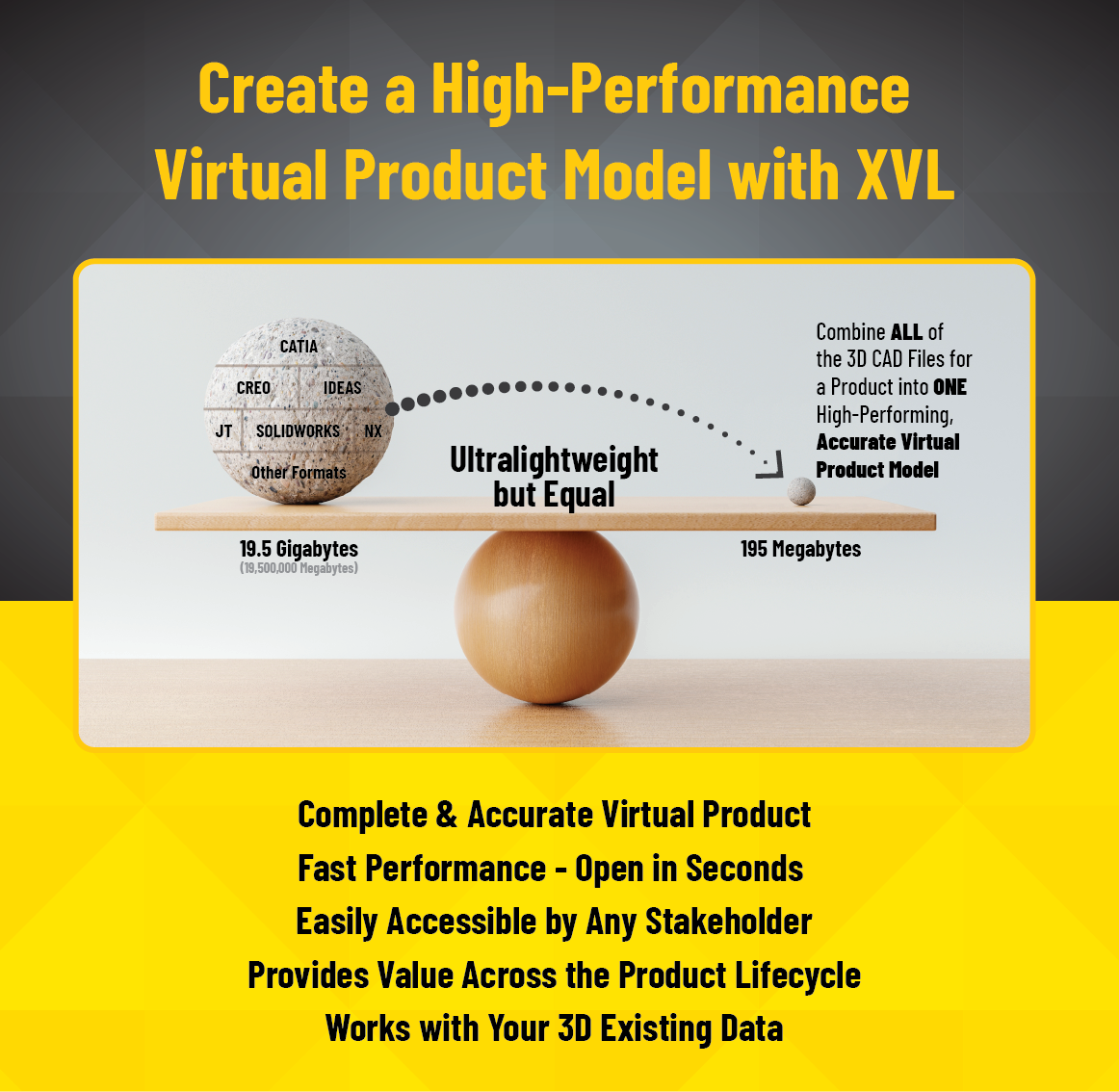

XVL allows the creation of a Virtual Product Model that can contain all of the 3D CAD files for the complete design, even different 3D CAD formats.

This Virtual Product Model is lightweight providing excellent performance, even on tablets.

Use the Virtual Product Model Across the entire lifecycle. It is much easier to use than PDM or PLM and XVL can integrate to those systems.

How can we help? Let us know your challenge.

Summary

Having an efficient product assembly process is crucial for the automobile manufacturing company. It affects everything from time-to-market to operational profitability to customer satisfaction.

In summary, manufacturing engineers are indispensable in creating clear and precise work instructions, based on thorough assembly process planning. With thousands of parts and many, many subsystems, this area is particularly challenging for automobile manufacturing. These areas are paramount for upholding consistency, ensuring quality control, and optimizing operational efficiency in automobile assembly.