How FURUNO Marine Electronics Utilizes Cutting-Edge XVL Technology to Revolutionize Manufacturing and Service Efficiency

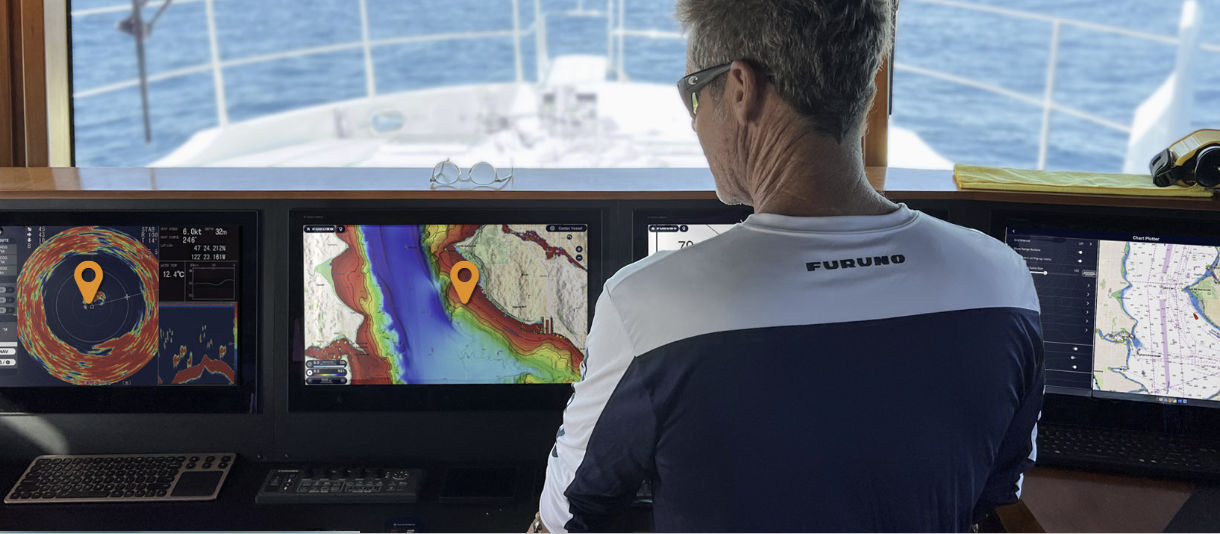

In the world of marine electronic equipment, efficient manufacturing, and service operations are essential to maintaining high-quality standards and operational excellence. FURUNO ELECTRIC CO., LTD., a leader in marine technology, has embraced XVL technology to streamline both its manufacturing and service operations. XVL’s ability to handle complex 3D CAD data in a lightweight yet highly detailed format has transformed how FURUNO optimizes assembly planning, service procedures, and technical support.

This blog explores how FURUNO’s manufacturing planners and service management teams use XVL to enhance efficiency, improve collaboration, and reduce downtime, ensuring that their marine electronic products are built and serviced precisely.

Using XVL, a 3D Digital Twin is created by combining all 3D CAD files used for the complete design of the product. The 3D Digital Twin retains CAD-level accuracy and includes all metadata (including Product Manufacturing Information—PMI) from the authoring 3D CAD system.

FURUNO has embraced XVL from Lattice Technology. What started as a single use case has evolved into implementing the XVL pipeline companywide. The XVL pipeline allows any stakeholder who needs product information easy access without using a 3D CAD application.

Read below about the benefits FURUNO has achieved from using XVL for manufacturing and service.

Manufacturing: How FURUNO Uses XVL to Improve Marine Equipment Manufacturing Efficiency

Manufacturing planners face daily challenges handling complex 3D CAD files. At FURUNO’s Miki Factory, XVL has become a game-changer in optimizing the manufacturing process for marine electronic products.

Key Benefits of XVL for Manufacturing Planners:

✔ Simplified CAD Data Handling – XVL consolidates multiple CAD files into a single, lightweight 3D model, making it easier to review complex assemblies without requiring CAD expertise or access.

✔ High-Performance Visualization – Despite XVL being ultralightweight (approximately 1/100th the size of the original 3D CAD files), the ultralightweight models still retain CAD-level accuracy for real work. This accurate, ultralightweight nature of XVL enables planners to interact with large models.

✔ Streamlined Collaboration – Manufacturing and engineering teams can work together seamlessly, eliminating costly errors before production starts.

✔ Enhanced Assembly Review & Planning – XVL allows planners to visualize assembly sequences and identify potential production problems virtually.

✔ Enhanced – From the virtual assembly plan, detailed interactive work instructions are created for the shop floor.

Real-World Impact

At FURUNO, stakeholders use XVL to validate complex assembly procedures before production, ensuring all parts fit correctly and manufacturing runs smoothly. This 3D Digital Twin approach significantly reduces errors, enhances efficiency, and accelerates production timelines, reinforcing FURUNO's reputation for quality marine electronics.

Service: How FURUNO Uses XVL for Efficient Service Operations and Technical Support

Beyond manufacturing, XVL is also transforming FURUNO’s service operations by improving technical support, field service procedures, and service documentation.

Key Benefits of XVL for Service Teams:

✔ 3D Digital Service Manuals – XVL enables the creation of interactive, lightweight 3D service manuals, making it easier for technicians to understand complex repair and maintenance procedures.

✔ Technician Training & Support – Field technicians can visualize 3D models of marine equipment, reducing the learning curve and improving troubleshooting efficiency.

✔ Faster Problem Resolution – Service teams can leverage XVL’s detailed 3D models to quickly identify parts, diagnose issues, and execute repairs with precision.

✔ Better Collaboration Between Service & Engineering – XVL bridges the gap between engineering and field service teams, ensuring up-to-date and accurate service documentation.

Real-World Impact

FURUNO’s Service Management Department uses XVL to provide technicians with real-time support. This support includes instant access to 3D models and service manuals. This ensures faster repairs and reduces vessel downtime. By leveraging XVL’s powerful 3D visualization, FURUNO enhances its service operations' accuracy, efficiency, and reliability.

Conclusion

XVL technology is revolutionizing the manufacturing and service of marine electronic products for FURUNO. From streamlining assembly planning to enhancing technician support, XVL’s ability to manage complex 3D data in a lightweight, accessible format makes it indispensable for FURUNO’s manufacturing and service teams.

By embracing XVL, FURUNO ensures higher efficiency, reduced errors, and improved collaboration across departments, reinforcing its position as a leader in marine technology innovation. Whether in manufacturing or service, XVL is enabling a culture of collaboration, helping FURUNO build and maintain the future of high-performance marine electronics.

Images Courtesy of FURUNO Electric Co., LTD