Revolutionizing the Design Review Process: Introducing XVL Studio's Enhanced Features for Manufacturing Companies

Effective collaboration and efficient decision-making are crucial for success in today's fast-paced manufacturing industry. Manufacturing executives and their teams face the challenge of engaging stakeholders from multiple departments during the Design Review Process.

Lattice Technology, a leading provider of innovative software solutions, is pleased to unveil the latest release of XVL Studio. Packed with powerful features, this update aims to streamline the Design Review Process and empower manufacturing executives with enhanced tools for engaging stakeholders and optimizing productivity.

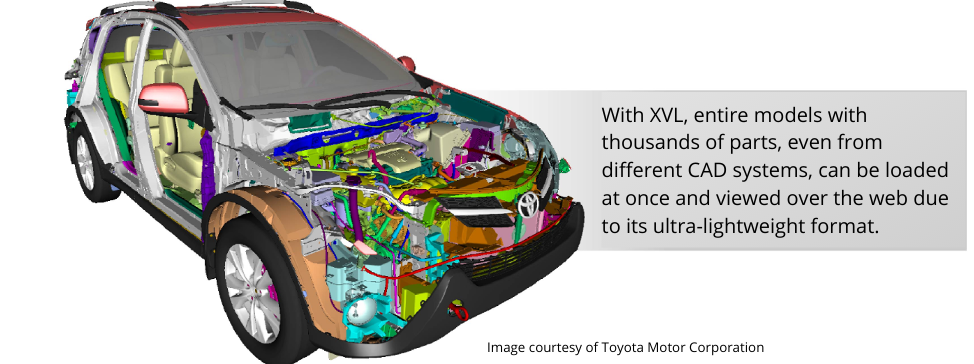

Work with the Entire Product

Using XVL, your team is able to work with your entire virtual product because the format retains CAD-level accuracy while at the same time being ultralightweight, about 1/100th the size of the original 3D CAD. This is extremely important with performing the final design check and planning for manufacturing.

Here is a brief overview of the enhancements.

Dynamic Collision Check

One of the standout features of XVL Studio is the Dynamic Collision Check. The ability to identify potential clashes between components in real time is invaluable. By catching these collisions early in the design phase, manufacturers can avoid costly rework and minimize time-to-market. With XVL Studio's dynamic collision check, stakeholders can ensure that all components fit together seamlessly, reducing the risk of unexpected issues during the manufacturing process.

Dynamic Measurement

Accurate measurements are vital in the Design Review Process, and XVL Studio's Dynamic Measurement feature delivers just that. With on-the-fly measurement capabilities, manufacturing stakeholders can obtain precise and reliable data during design reviews. This empowers decision-making and facilitates effective communication between stakeholders with the tools they need to integrate the complete product model.

Workability Check

Workability Check is another valuable enhancement in XVL Studio. By evaluating workability early on, manufacturing executives can identify potential production challenges and make informed design adjustments before committing to manufacturing. This proactive approach saves time and resources, ultimately resulting in a smoother manufacturing process.

Advanced Annotation/Markups

Collaboration and communication are key in any design review, and XVL Studio addresses this need with its Advanced Annotation/Markups feature. This feature enables stakeholders to provide comprehensive documentation and feedback directly within the software. By streamlining the exchange of ideas and feedback, XVL Studio ensures that all stakeholders are on the same page, reducing misunderstandings and promoting efficient decision-making.

Tools, Jigs, and Fixtures

This powerful feature enables these manufacturing tools to be included in your manufacturing planning.

Automatic Path Finder

Navigating through complex designs can be a time-consuming task, but XVL Studio's Automatic Path Finder feature offers a solution. This feature automatically identifies the optimal path for assembly or disassembly, minimizing errors and reducing assembly time. Manufacturing executives can optimize workflow efficiency and simplify navigation, leading to improved productivity and reduced costs.

"We are excited to introduce the latest version of XVL Studio, specifically designed to support manufacturing in streamlining their Design Review Process," said Chris Hughes, Product Marketing at Lattice Technology. "With the enhanced features in this release, stakeholders from multiple departments can collaborate seamlessly, enabling faster decision-making and ensuring the highest level of design quality. We believe that XVL Studio will revolutionize how manufacturing organizations approach the design review phase."

The new release of XVL Studio is now available for manufacturing executives seeking to enhance their Design Review Process. By leveraging the power of these advanced features, manufacturing teams can overcome challenges, improve collaboration, and optimize productivity.

Learn More

Do you have a question about your environment and how XVL could benefit your company? Click below to submit your question.