Get Our Latest eBook: Overview of Creating Work Instructions from ANY 3D CAD

The Starting Point for Quality Manufacturing Assembly Instructions is Planning

Thorough planning is the foundation for creating high-quality manufacturing work instructions. With thousands of parts and multiple subsystems, this is particularly important for industries such as automotive, industrial machinery, and heavy equipment manufacturing—where complex assemblies require meticulous organization.

Each assembly step must be planned considering several factors. What is the most efficient assembly process? There may be hundreds or even thousands of steps for a complex product, so determining the correct order in crucial. Proper planning yields significant benefits once production begins, reducing inefficiencies and ensuring smooth operations.

Well-structured planning and precise work instructions are essential for maintaining consistency, improving quality control, and enhancing operational efficiency in manufacturing.

1. Consistency in Operations:

Clear and standardized work instructions ensure that every worker follows the same process, promoting consistency in manufacturing operations. Whether assembling an automobile’s transmission system, an industrial robotic arm, or a hydraulic excavator’s boom, consistency prevents variation and ensures that each product meets the same high standards.

Clear and standardized work instructions ensure that every worker follows the same process, promoting consistency in manufacturing operations. Whether assembling an automobile’s transmission system, an industrial robotic arm, or a hydraulic excavator’s boom, consistency prevents variation and ensures that each product meets the same high standards.

2. Quality Control:

Precise assembly instructions provide better control over product quality. For instance, clear guidelines for assembling automotive safety components (e.g., braking systems), industrial machine tool alignments, or hydraulic circuits in heavy equipment ensure reliable performance and long-term durability.

3. Reduced Errors and Rework:

Ambiguous instructions often lead to costly mistakes, requiring rework. By eliminating guesswork, manufacturers can reduce defects. For example, well-defined assembly instructions for electronic control units in vehicles, precision bearings in CNC machines, or hydraulic pumps in bulldozers help prevent costly errors that could impact performance.

Ambiguous instructions often lead to costly mistakes, requiring rework. By eliminating guesswork, manufacturers can reduce defects. For example, well-defined assembly instructions for electronic control units in vehicles, precision bearings in CNC machines, or hydraulic pumps in bulldozers help prevent costly errors that could impact performance.

4. Efficiency Improvement:

Detailed and well-organized work instructions streamline production, increasing efficiency. A clearly documented process for assembling an automobile chassis, a robotic welding machine, or the drivetrain of a wheel loader helps reduce production time while maintaining high accuracy and repeatability.

5. Training and Onboarding:

Clear work instructions make it easier to train and onboard new employees quickly. New assembly line workers in an automotive factory, technicians assembling a high-precision industrial lathe, or welders constructing a dump truck frame all benefit from structured training materials that reduce the learning curve.

6. Standardization:

Standardized instructions help ensure that all production facilities follow the same best practices, regardless of location. Standardized instructions maintain uniformity and compliance across operations, whether assembling a mass-produced vehicle, robotic automation systems, or hydraulic actuators.

7. Risk Mitigation:

Ambiguous instructions can result in safety hazards. Clear and precise instructions help reduce workplace accidents. For example, step-by-step instructions for handling high-voltage battery packs in electric vehicles, heavy-duty presses in industrial machinery, or hydraulic lifts in construction equipment improve worker safety and regulatory compliance.

Ambiguous instructions can result in safety hazards. Clear and precise instructions help reduce workplace accidents. For example, step-by-step instructions for handling high-voltage battery packs in electric vehicles, heavy-duty presses in industrial machinery, or hydraulic lifts in construction equipment improve worker safety and regulatory compliance.

8. Communication and Collaboration:

Clear work instructions enhance communication between design, engineering, and production teams. When assembling a vehicle’s infotainment system, a precision conveyor system for a manufacturing plant, or a crane’s hoist mechanism, structured instructions ensure design intent is accurately translated into production.

9. Regulatory Compliance

Manufacturing industries must adhere to strict regulatory standards. Well-documented assembly instructions help ensure compliance with automotive safety and emissions regulations, industrial machine safety protocols, and heavy equipment load-bearing standards—all of which are critical for legal and operational integrity.

Manufacturing industries must adhere to strict regulatory standards. Well-documented assembly instructions help ensure compliance with automotive safety and emissions regulations, industrial machine safety protocols, and heavy equipment load-bearing standards—all of which are critical for legal and operational integrity.

10. Customer Satisfaction:

Consistently producing high-quality products that meet specifications results in greater customer satisfaction. Whether it's an industrial milling machine that delivers high precision or a bulldozer built for rugged durability, well-documented assembly processes contribute to a product that exceeds customer expectations.

Consistently producing high-quality products that meet specifications results in greater customer satisfaction. Whether it's an industrial milling machine that delivers high precision or a bulldozer built for rugged durability, well-documented assembly processes contribute to a product that exceeds customer expectations.

How Can XVL Benefit these Endeavors?

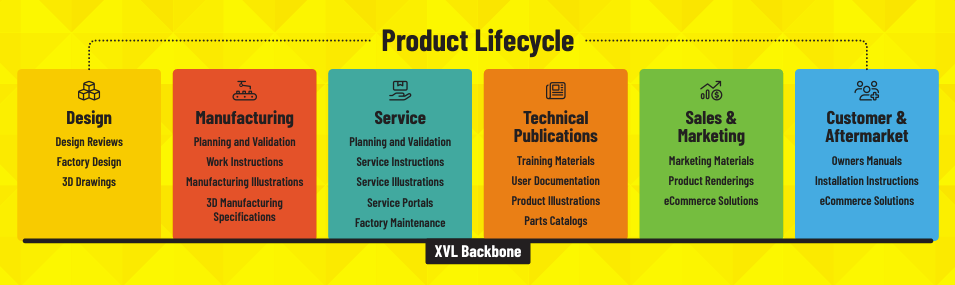

XVL allows the creation of a 3D Digital Twin that contains all of the 3D CAD files for the complete product, even different 3D CAD formats.

This 3D Digital Twin is lightweight, providing excellent performance, even on tablets.

Use the 3D Digital Twin throughout the lifecycle. It is much easier to use than PDM or PLM, and XVL can integrate with those systems.

Summary

An efficient assembly process is critical for any company manufacturing complex products. It impacts everything from production speed and cost efficiency to regulatory compliance and customer satisfaction.

In summary, manufacturing engineers play a crucial role in developing clear and precise work instructions—grounded in meticulous assembly process planning. With hundreds or thousands of parts and multiple subsystems, manufacturers face many challenges in maintaining consistency, quality control, and operational efficiency. By implementing well-structured assembly instructions, manufacturers can reduce errors, improve worker safety, streamline production, and enhance product reliability—leading to a more competitive and resilient manufacturing process.

Next Steps

Learn More

We have lots of resources in our Knowledge Center from Customer Case Studies to Whitepapers to Introductory Videos (each around 3 minutes).

Ready for a Discussion?

How about a call with one of our Solution Architects to discuss your unique challenges?