Use a 3D Digital Twin for Manufacturing Planning

Optimize Your Assembly Processes.

Virtual Assembly Planning & Simulation

What If?

During manufacturing planning, you could:

- Combine all 3D CAD files from the design department into a single Virtual Product Model, even across multiple formats

- Use this Virtual Product Model for all planning

- Generate any number of BOMs directly from the same data, Manufacturing BOM (mBOM), Service BOM (sBOM), and more

- Virtually assemble the product by dragging and dropping each part

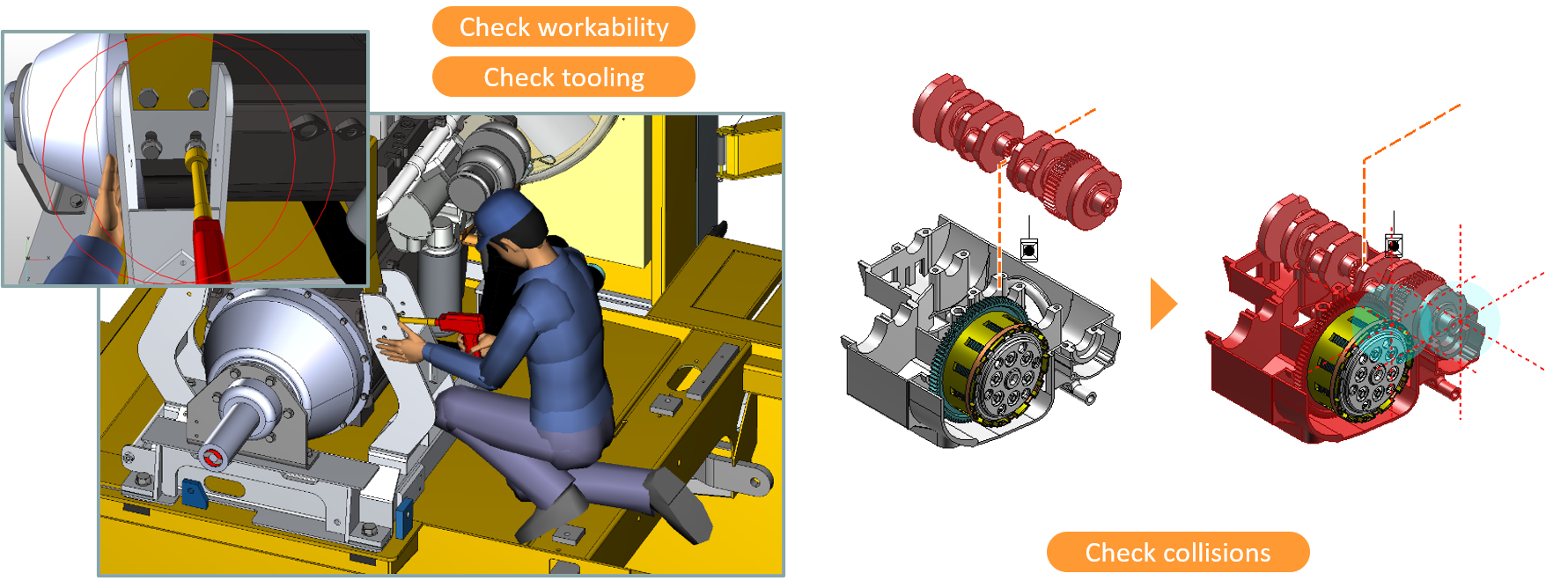

- Check part travel clearance, tool access, and human access while building - all virtually

- Simulate the entire assembly process to identify potential issues and optimize the manufacturing workflow

Would that benefit your company? If so, we can help. What we call the 3D Digital Twin using XVL from Lattice Technology enables this.

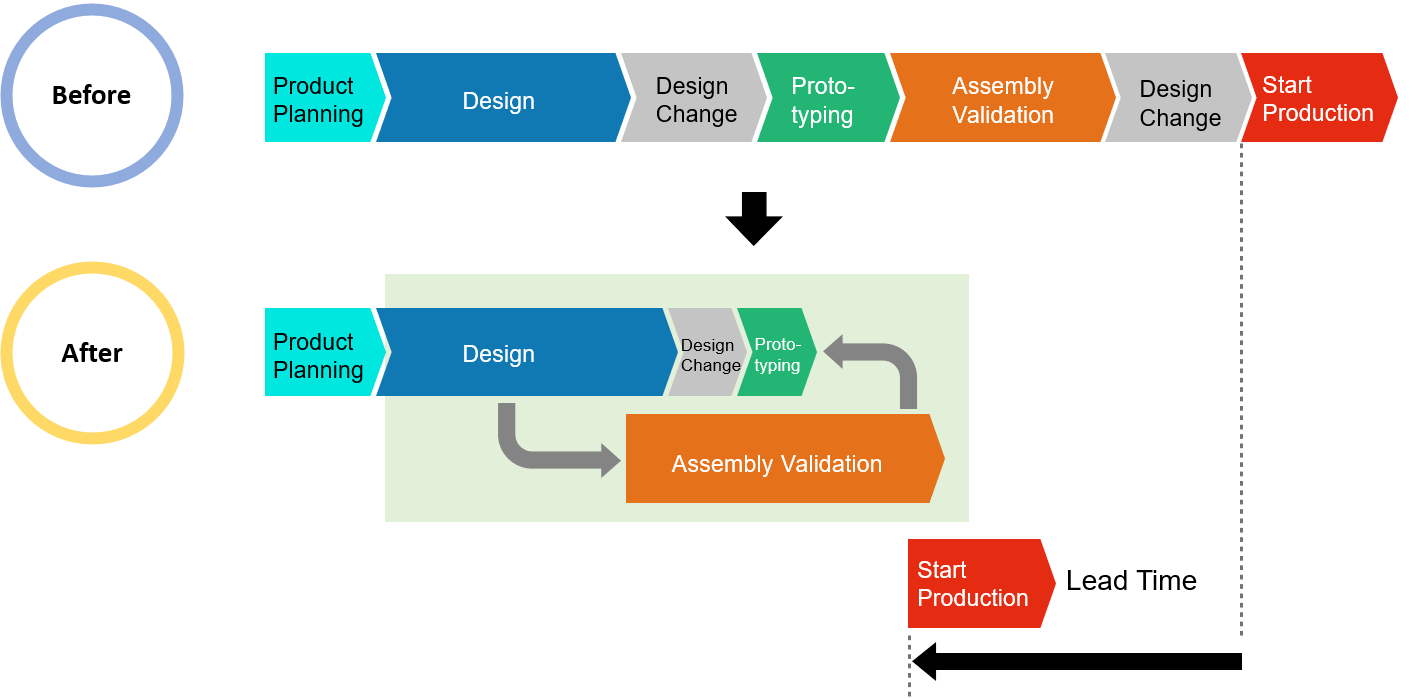

Common Challenges Experience by Most Companies Today

The traditional assembly validation process starts after the design is released, often relying on physical prototypes to develop and test assembly procedures. If issues are discovered, they may require changes to the assembly process or even the product design. The longer these issues go undetected, the more expensive they are to resolve. Problems found after production begins are the most costly, as they disrupt production and may require design changes, process updates, and the scrapping of existing parts.

- Assembly planning and validation typically begin after design completion, leading to delays in identifying assembly issues

- Physical prototypes are often needed for assembly validation, which are time-consuming and costly to produce

- Digital assembly validation tools frequently struggle with large models due to hardware and software constraints

- Design changes usually necessitate slow and expensive revalidation of previous results

Using a 3D Digital Twin Will Speed up Your Planning and Give you Better Results

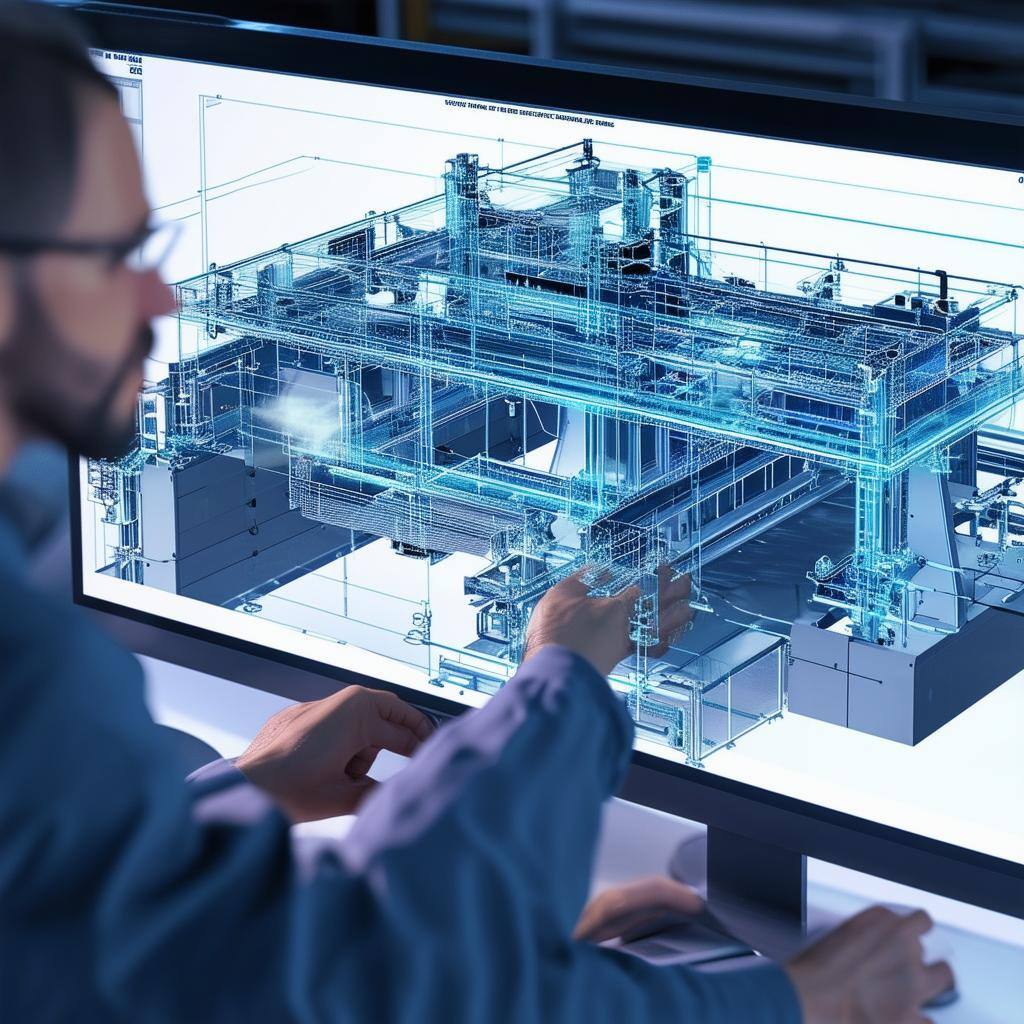

3D Digital Twin

Lattice Technology's assembly validation solution addresses these challenges by converting heavy 3D CAD data into lightweight XVL that we call a 3D Digital Twin. This enables easy definition of assembly processes using Lattice Technology tools. The lightweight data allows full 3D model visualization and validation, enabling digital assembly validation without waiting for design completion or depending on physical prototypes.

No More Physical Prototypes

Lattice Technology reduces or even eliminates the need for physical prototypes by allowing you to validate the entire assembly process using design data alone. By identifying and resolving assembly issues before the design is finalized, you ensure the process is validated when the design is released. While physical prototypes can still be used to check the assembly process, you will require far fewer of them. Over time, physical prototypes may become unnecessary altogether.

Virtual Validation of the Assembly Plan

With Lattice Technology, you can validate the entire assembly process using the complete 3D Digital Twin, even for products with 100s or 1,000s of parts. Our software efficiently handles large models, allowing you to perform a single validation check without splitting the model into subassemblies. This streamlines the process, reducing the need for multiple independent checks. By validating all parts simultaneously, you also minimize the risk of overlooking any issues that might have been missed in separate checks.

Detailed Validation

Lattice Technology goes beyond assembly process validation by offering tools to evaluate other critical aspects of production. This includes the use of human mannequins to ensure safety and ergonomics, as well as incorporating tools and fixtures to assess operational feasibility. These and many other features are available within the Lattice Technology solutions, providing a comprehensive approach to process evaluation.

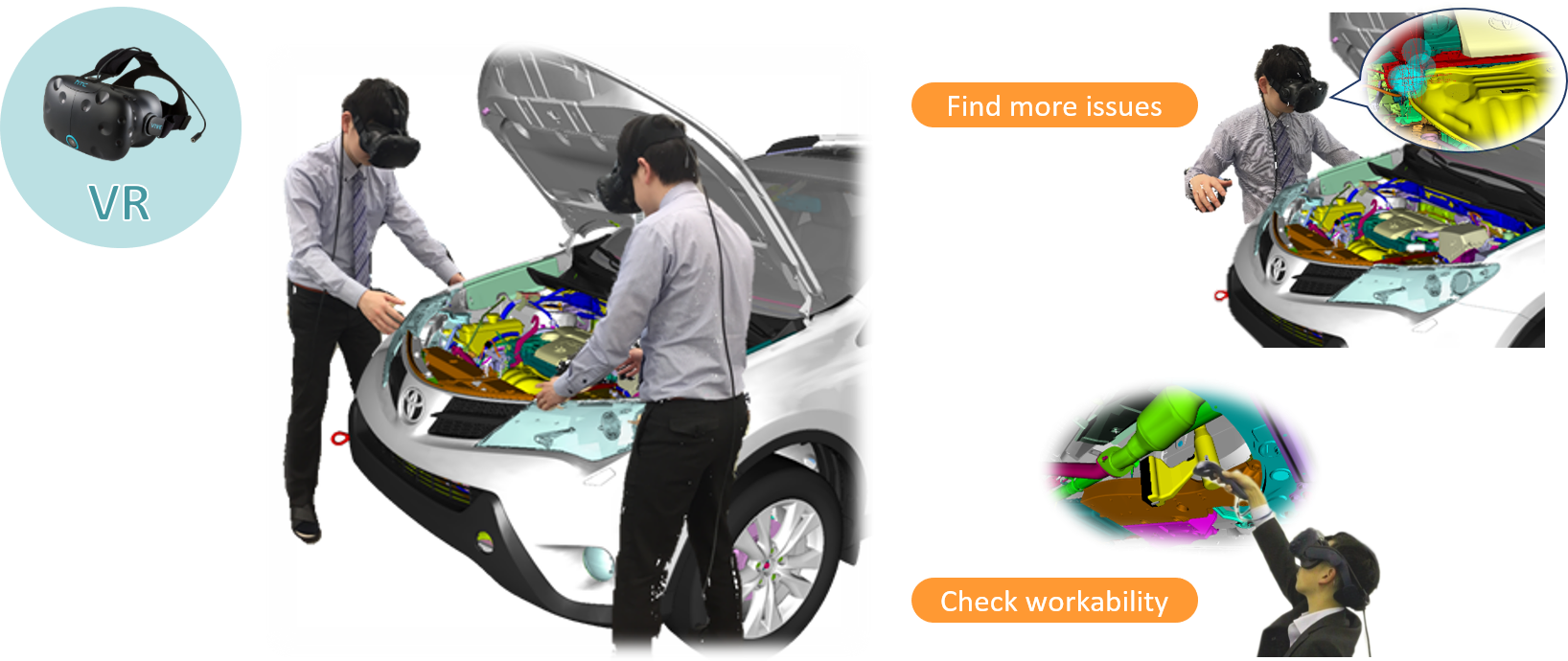

Visualize in Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR)

Lattice Technology enables you to visualize your processes in virtual reality, offering a full-scale 3D model experience. This immersive perspective allows you to spot issues that might be overlooked in traditional digital verification, giving you greater control and improving the accuracy of the validation process.

And because your 3D Digital Twin is already ultralightweight, the complete data model can we brought into various VR, AR, and MR systems without manipulating the data.

Learn More

How can we help? Click below to send us a question about a problem you would like to solve.