How Mitsubishi Made Radical Manufacturing Improvements by Extending the Use of their PTC/Creo 3D Design Data

Mitsubishi Agricultural Machinery (MAM) was using PTC/Creo for 3D modeling components in their Combine Harvester product line. Using Creo from design was powerful for Mitsubishi.

However, using the 3D CAD data beyond the design division proved challenging due to the large model sizes and the number of CAD files necessary for the entire product. This issue prompted MAM's adoption of XVL for downstream processes (from design). Since then, MAM has expanded its utilization of XVL to involve stakeholders across the organization.

This blog article covers the two broad areas Mitsubishi was able to better leverage their 3D CAD data from PTC/Creo.

- Product Manufacturing Process Planning

- Transitioning from Paper-Based Processes to Electronic - Digital Transformation

Using XVL to Overcome Challenges in Product Manufacturing Process Planning

This spans from release to manufacturing to producing electronic work instructions for the assembly floor. The following were just some of the issues Mitsubishi faced:

- Limited collaboration with the design division.

- Inability to view the entire assembly structure or the process planning procedure.

- Tedious creation of 2D illustrations for the assembly process sheet, with design changes being omitted due to the absence of quick and easy data updating and sharing.

MAM had two primary objectives in implementing XVL in production process planning. The first objective was to "front-load" the process design by utilizing the assembly tree structure in XVL to detect and address production issues at an early stage. The second objective was to expedite the generation of assembly process instructions by automating as much of the process as possible.

Mitsubishi chose XVL for production process planning due to its lightweight nature, accuracy, excellent 3D performance, and ease of assembly process instruction creation. Furthermore, XVL's flexibility extends its utility to enhance organizational processes, from design to sales.

Below are the details.

New and Enhanced Production Planning Process

Before implementing XVL, assembly process planning only commenced after receiving approved drawings. With XVL, assembly process planning can now start during the design phase, allowing for the early detection and resolution of assembly issues. Furthermore, MAM has improved productivity by creating digital work instructions directly from the PTC/Creo 3D CAD files for the shop floor.

MAM now leverages XVL for assembly process planning and creating work instructions, which encompass four steps:

- Creating the assembly tree structure (mBOM)

- Defining work processes

- Allocating shop floor resources

- Exporting the assembly tree (mBOM).

Below are the stages used by MAM from manufacturing planning to delivering electronic work instructions to the shop floow.

Initial Manufacturing Planning – Stage 1

In the first stage, MAM designs the fundamental assembly processes in XVL Studio, grouping parts for sub-assembly. The assembly order can be adjusted, as needed, for detailed manufacturing process planning, with parts added or repositioned using XVL Studio. As this work is extensive, it is shared and distributed among planning team members. XVL Studio simplifies the merging of process trees and the addition of sub-assembly processes, expediting the creation of the complete assembly process.

Man-Hour Calculations – Stage 2

Previously, MAM utilized Excel for man-hour calculations and critical assembly instructions. With XVL, such information is stored as attributes in the XVL file, facilitating man-hour calculations and assembly instruction generation.

Resource Allocation – Stage 3

In the third stage, shop floor resources are allocated to each process. Line shares and shop floor allocations can be swiftly accomplished.

Assembly Plan Validation – Stage 4

Stage four incorporates basic customization of XVL Studio, enabling Mitsubishi to quickly identify the assembly structure and parts attributes and verify line loads using man-hour calculations.

Process Instruction Creation – Stage 5

MAM employs XVL Studio to create process animations, capturing snapshots of these animations for use as illustrations in process instructions. XVL Studio also facilitates annotation with 3D Snapshots with essential process information.

Process Instruction Export – Stage 6

MAM has customized XVL Studio with an export function to output saved 3D Snapshots and process information. This exported data is directly stored in an assembly process information sheet.

Transitioning from Paper-Based Processes to Electronic - Digital Transformation

When MAM introduced 3D technology into its product development, its downstream applications still relied on paper reports and drawings for delivering assembly process information. Despite the introduction of 3D, the design, product planning, and production divisions continued to rely on traditional 2D methods (paper-based and sometimes 2D electronic), causing delays and frustrations. For example, the product planning division awaited hard copy drawings from the design division, and the production division had to wait for the hard copy assembly process management sheet. This resulted in protracted delays, as manufacturing planning was contingent on receiving instructions from each division.

Flexible Manufacturing Model

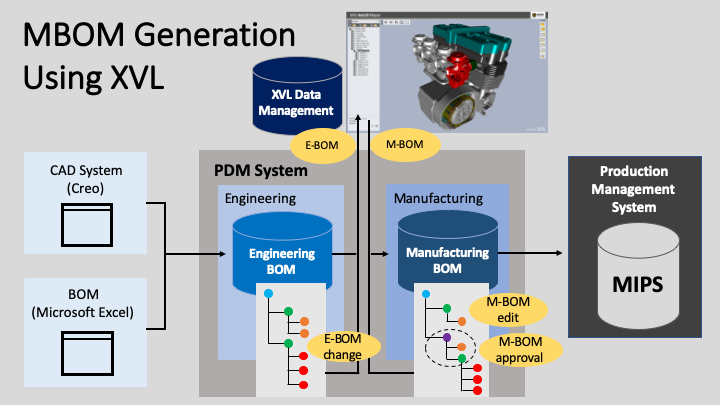

By using XVL, MAM transitioned from a paper-based process to an electronic-based process (Digital Transformation), reducing lead times and inventory levels. This transformative process is known within the company as the "Flexible Manufacturing Method." This method employs the manufacturing assembly BOM (commonly called the mBOM) to track part-level information, such as suppliers and inventory, which is distinct from the eBOM created from the Creo-designed structure tree.

BOMs

MAM utilizes Lattice XVL Studio to develop and maintain the assembly mBOM in XVL. XVL and Lattice applications accommodate multiple bills of material (eBOM (engineering), mBOM (manufacturing), sBOM(service)), allowing the same model to be used for various purposes. The assembly BOM crafted within XVL is then forwarded to the MAM Mix Production System (MIPS), which manages the parts procurement process automatically.

Results and Thoughts for the Future

Through the transformation of assembly process planning and work instruction methods, Mitsubishi has realized benefits in terms of faster planning and improved process design.

Engineers responsible for assembly process planning have expressed satisfaction with the new system, as it allows them to visualize the entire assembly process in 3D, simplifying the design of individual assembly processes. Expectations for 3D data utilization on the shop floor have risen, driven by XVL's ability to display assembly structures, processes, and work instructions. This has encouraged shop floor staff to embrace 3D as a tool, departing from conventional methods.

MAM envisions further enhancements in assembly process design and distribution with XVL. XVL facilitates the automatic transfer of critical assembly information from CAD files as 3D annotations, potentially eliminating the need for traditional 2D drawings in manufacturing. The company plans to digitally distribute the results of process designs, focusing on the transition to paperless processes using 3D as the primary medium.

End users within the company have begun to recognize the effectiveness of XVL through tools like Lattice 3D Reporter (for publishing interactive 3D product and related data to Microsoft Excel and 3D PDF) and XVL Web Master (publishing for consumption by any HTML5-based web browser)> This enables MAM to rapidly provide information and data to stakeholders, without relying on paper reports and drawings.

Mitsubishi Agricultural Machinery has reaped the benefits of improved assembly process design by adopting XVL and anticipates even more significant improvements in the future.

Want to Learn More?

Send us your question by following the link below.