Get More Use from your 3D CAD Models with These 6 XVL Solutions

Published by

Chris Hughes

on

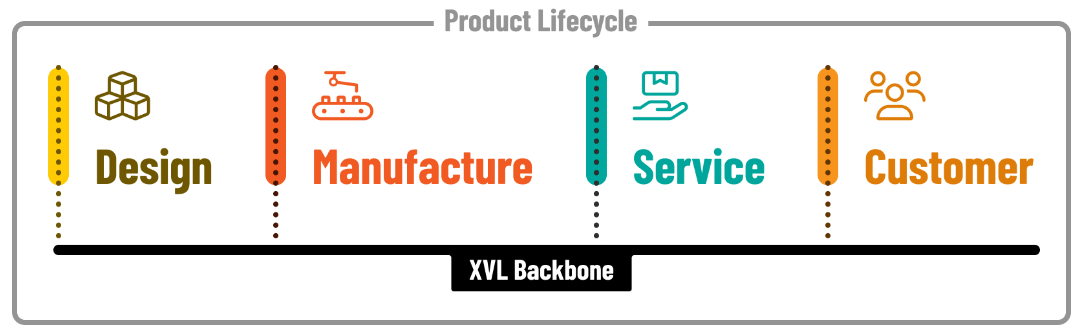

XVL, from Lattice Technology, takes off from where your 3D CAD systems stop.

Challenges of Using 3D CAD Downstream from Design

Everyone knows 3D CAD files are difficult to deal with:

- They can be extremely large, in the gigabytes.

- A single product may have 10s, 100s, or even 1,000s of 3D CAD files.

- The 3D CAD files may be in different formats, SOLIDWORKS, CREO, Catia, NX, or JT - to name a few.

- CAD licenses are expensive and require a high level of expertise to use.

- Viewers are just that. They stop well short of being able to leverage the 3D models for other use cases. And they have difficulty with the different formats and many files.

XVL solves all of that and much more. XVL was designed to leverage the 3D CAD files from the design department to provide utility to the rest of the organization.

Virtual Product Model

With XVL, all of the native (not neutral, dumbed down formats) 3D CAD models for a product can be combined into a single file.

The file sizes are compressed to about 1/100th the size of the original CAD file, which retains CAD-level accuracy.

You now have a single file for your entire product that is high-performance and has all of the data from your native CAD system. We call it the Virtual Product Model.

XVL Solutions

We offer 6 solutions.

- Design Review

.png?width=400&height=241&name=image%20(12).png) Perform design reviews on your entire product easily. Automatically detect design issues. Easily include others to bring in outside perspectives. Find and fix issues early to improve quality, reduce costs and shorten time-to-market.

Perform design reviews on your entire product easily. Automatically detect design issues. Easily include others to bring in outside perspectives. Find and fix issues early to improve quality, reduce costs and shorten time-to-market.

- Common Challenges

- Design review solutions often cannot handle large models due to software and hardware limitations.

- Design reviews usually require expensive software and high-end hardware.

- Design review solutions can miss issues, which become more expensive to fix later.

- Common Challenges

- Assembly Process Validation

.png?width=400&height=224&name=image%20(13).png) Perform virtual assembly validation. Start validating the assembly process as soon as preliminary designs are released -- no need to wait for prototypes. Find and fix issues early to improve quality, reduce costs and shorten time-to-market.

Perform virtual assembly validation. Start validating the assembly process as soon as preliminary designs are released -- no need to wait for prototypes. Find and fix issues early to improve quality, reduce costs and shorten time-to-market.

- Common Challenges

- Assembly planning and validation often start after the design is complete, delaying the discovery of assembly issues.

- Assembly validation often requires physical prototypes that are slow and expensive to produce.

- Digital assembly validation solutions often cannot handle large models due to hardware and software limitations.

- Design changes usually require slow and costly revalidation of previous results.

- Common Challenges

- Work Instructions

.png?width=400&height=151&name=image%20(14).png) Use your 3D CAD models to create accurate work instructions. Easily create 2D illustrations and 3D animations to make the instructions easy to follow. Automatically update the work instructions when the design changes.

Use your 3D CAD models to create accurate work instructions. Easily create 2D illustrations and 3D animations to make the instructions easy to follow. Automatically update the work instructions when the design changes.

- Common Challenges

- Authoring work instructions cannot typically commence until a physical prototype is developed.

- Authoring work instructions with photos and text can be cumbersome and time-consuming.

- Updating work instructions when the design changes can be expensive.

- Common Challenges

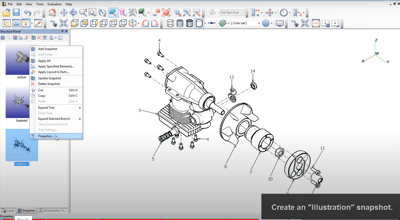

- Technical Illustrations

Use your 3D design data to quickly and easily create technical illustrations. Maintain consistent illustration quality throughout the department. Automatically update the illustrations when the design changes.

Use your 3D design data to quickly and easily create technical illustrations. Maintain consistent illustration quality throughout the department. Automatically update the illustrations when the design changes.

- Common Challenges

- Creating technical illustrations by hand traditionally requires physical mockups or photographs for reference.

- It is difficult to maintain consistent quality when creating manual illustrations.

- When the model changes, you must recreate the illustration from scratch.

- Common Challenges

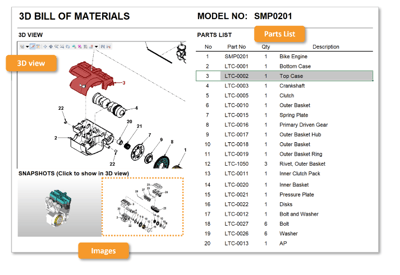

- Technical Documentation

Use your existing 3D design data to easily create rich interactive technical documentation. Improve communications in engineering, manufacturing, service, and even outside your organization. Publish in a variety of formats, including web, Microsoft Excel, 3D PDF, 2D PDF and more.

Use your existing 3D design data to easily create rich interactive technical documentation. Improve communications in engineering, manufacturing, service, and even outside your organization. Publish in a variety of formats, including web, Microsoft Excel, 3D PDF, 2D PDF and more.

- Common Challenges

- Technical documentation is often difficult and time-consuming to produce.

- Traditional technical documents are static and lack interactivity.

- Manually keeping documentation up to date is difficult and error-prone.

- Common Challenges

- Electronic Spare Parts Catalogs and Service Portals Extend the use of your 3D models into service and support.

- Spare Parts Catalogs

- Create an interactive graphical-based parts catalog from the Virtual Product Model.

- Service Portals

- Provide all of your service procedures as interactive work instructions.

- Spare Parts Catalogs

Want to Learn More?

Send us your question by following the link below.