Concurrent Engineering: Improving How Product Design Works with Manufacturing to Accelerate Time-To-Market - 5 Ways XVL Assists

Multiple 3D CAD formats can be combined into a single XVL file, creating a Virtual Product Model that is CAD-accurate and about 1/100th the size of the original CAD files enabling both teams to use a single data model for collaboration.

Be sure to read the Mitsubishi Case Study - link near the bottom of this post.

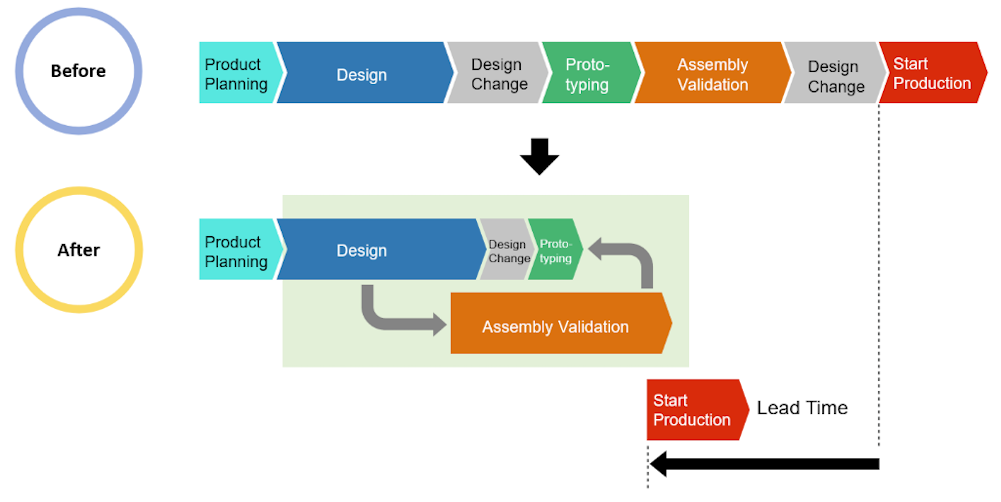

Concurrent Engineering stands as a pivotal methodology for manufacturing companies, forging a seamless connection between product design and manufacturing. In this context, the incorporation of XVL technology is a game-changer, amplifying the collaborative efforts between design and manufacturing teams. Let's explore how XVL enhances Concurrent Engineering through real-world examples and tangible benefits.

1. Effortless Data Integration:

XVL streamlines the use of 3D CAD data, allowing design and manufacturing teams to work with a unified, lightweight model. Imagine a scenario where complex 3D CAD files (from essentially any major 3D format, even combining multiple formats into a single file) are quickly and easily converted into XVL, providing a common platform for both teams. This not only accelerates decision-making but also ensures that everyone is working with the most up-to-date and accurate information.

2. Real-Time Collaboration:

With XVL, collaboration between design and manufacturing becomes a dynamic, real-time process. Picture engineers making design adjustments in 3D models while manufacturing teams can seamlessly evaluate the impact on assembly processes. This collaboration ensures that any potential issues are identified and addressed in the early stages, preventing bottlenecks downstream.

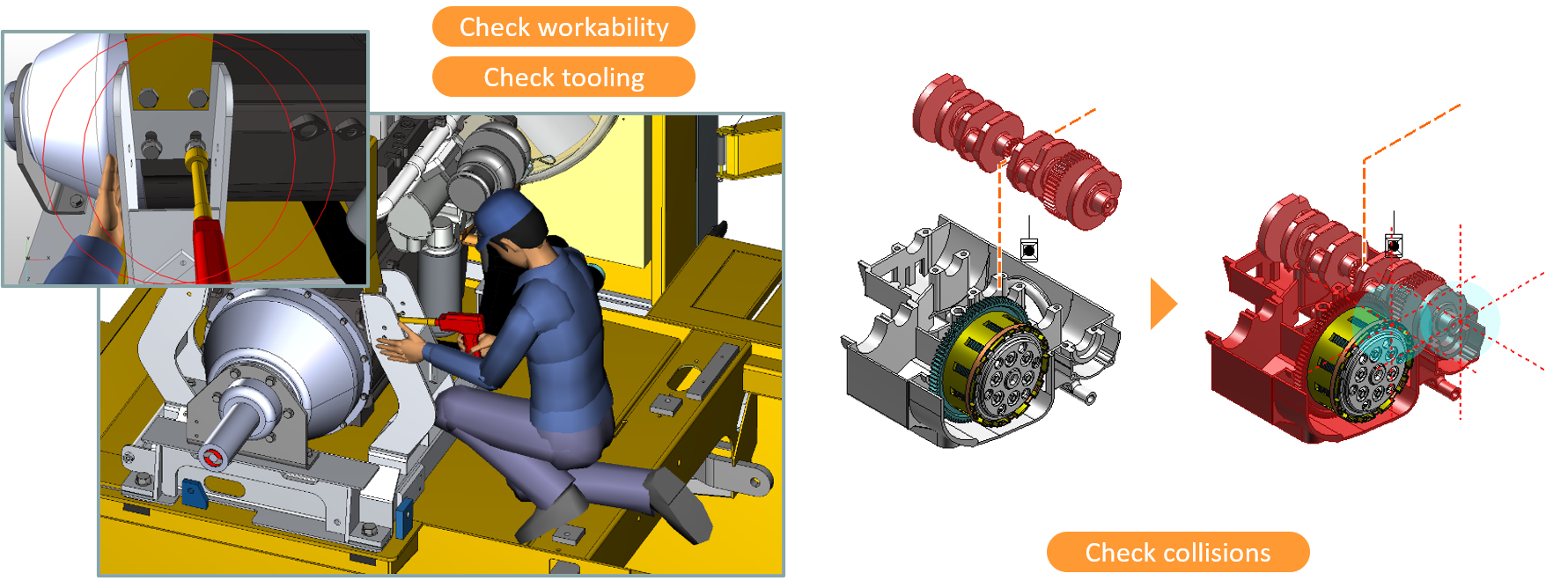

3. Visualizing Assembly Processes:

XVL's advanced visualization capabilities allow teams to virtually simulate assembly processes. Consider a scenario where engineers use XVL to visualize the entire assembly process, identifying part travel clearance, tool access, and human interaction points. This not only optimizes the assembly workflow but also ensures that the final product is manufacturable with minimal adjustments.

4. Reducing Physical Prototypes:

XVL significantly diminishes the need for physical prototypes. Imagine a scenario where a company traditionally relied on multiple physical prototypes for validation. With XVL, the entire assembly process can be digitally validated, eliminating the time and cost associated with creating numerous physical prototypes. This translates to faster iterations and reduced time-to-market.

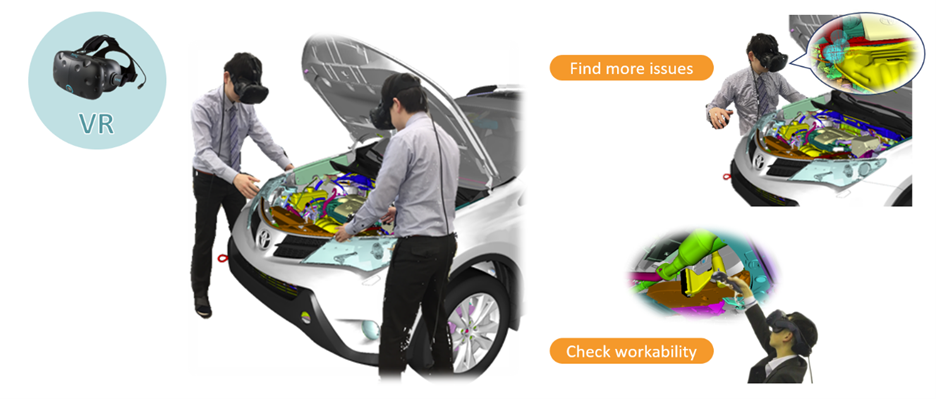

5. Immersive Visualization in VR/AR/MR:

XVL takes Concurrent Engineering a step further by easily enabling immersive visualization in Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR). Yes, this can be done with other data models, but what makes XVL unique is that the format can be used without "dumbing down" the model. With XVL, data is already compressed to 1/100th the size of the originating CAD files (while maintaining CAD-level accuracy). Picture design and manufacturing engineers immersing themselves in a virtual environment, exploring full-scale 3D models to identify potential issues. This not only enhances the accuracy of the validation process but also provides a unique perspective not achievable through traditional methods.

CASE STUDY – Mitsubishi's Success

Consider the success story of Mitsubishi, a company leveraging XVL for advanced assembly processes. By adopting XVL in their Concurrent Engineering approach, Mitsubishi achieved significant improvements in collaboration, reduced reliance on physical prototypes, and accelerated their time-to-market. Their experience serves as a testament to the tangible benefits of integrating XVL in Concurrent Engineering practices.

Conclusion

Incorporating XVL into Concurrent Engineering practices not only addresses the challenges but propels manufacturing companies towards a future where collaboration, efficiency, and innovation converge. By visualizing and optimizing processes in real-time, XVL empowers companies to achieve unified engineering excellence, ensuring a competitive edge in the ever-evolving landscape of modern manufacturing.

Learn More

We have several customers who use XVL for this concurrent engineering. Mitsubishi is one; click here to read their story.

How Can We Help?

Click below to send us a question about a problem you would like to solve.