3D Drawings: Do They Make Sense for Your Company?

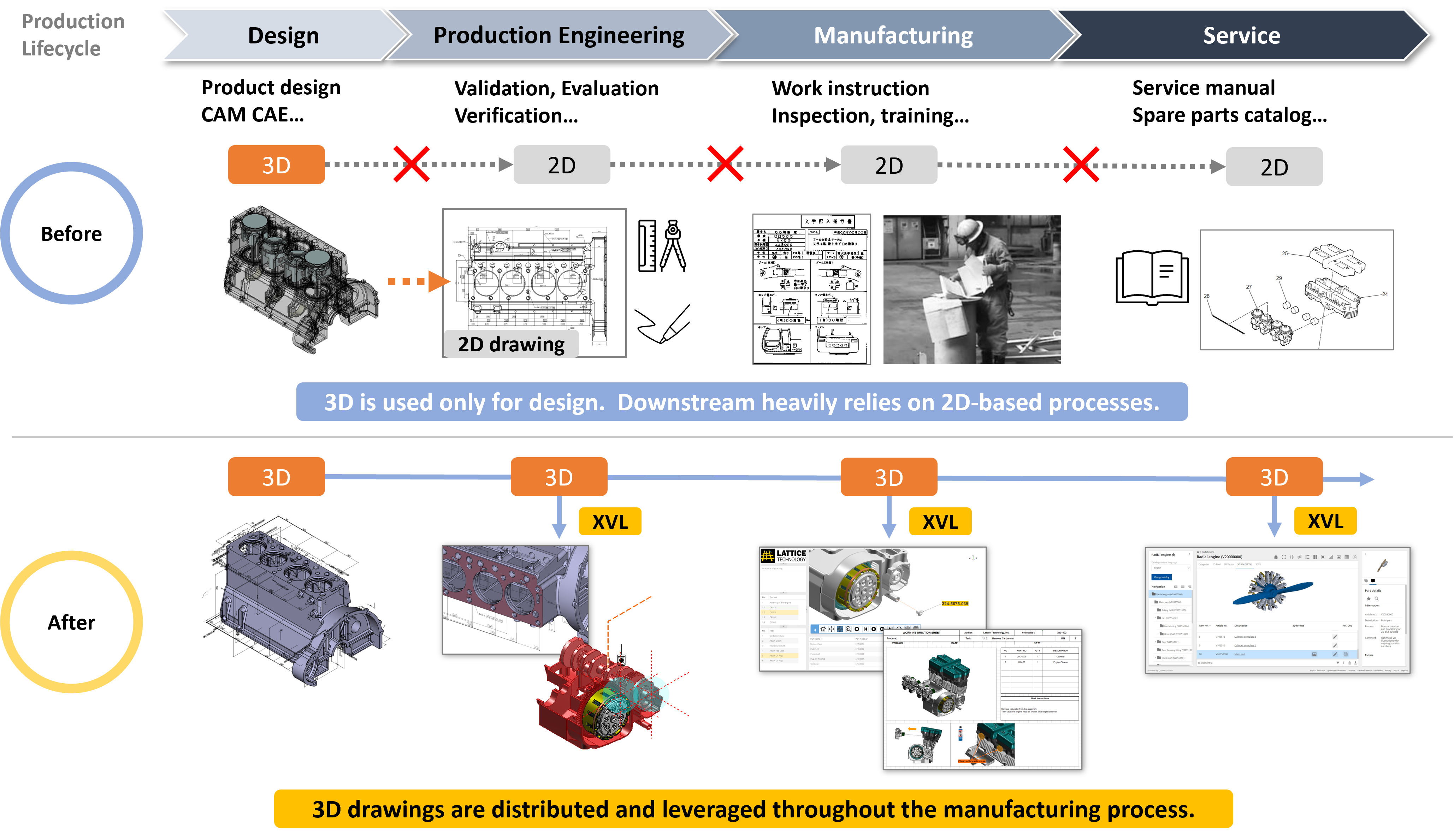

Many Companies are Transitioning from 2D Drawings

You have undoubtedly heard of Model-Based Design (MBD) and the Model-Based Enterprise (MBE). These initiatives aim to make the 3D model the single source of truth and to migrate away from 2D Drawings.

However, your company does not need to embark on one of these daunting initiatives to reduce dependency on 2D drawings. 3D Drawings from Lattice Technology using XVL allows you to do so while minimizing negative impacts.

This could be your first step along the path of Digital Transformation.

The Problems with 2D Drawings

Have you ever looked at a 2D drawing, even studied it, and still had trouble interpreting it? Of course, you have. 2D drawings are an abstraction and can be very confusing.

- Incomplete: Is there a dimension missing? Is a feature not documented?

- Ability to Explore. There is no way to explore a 2D drawing - it is how it is. Have you ever wanted to view a 2D drawing from a different perspective, as if you were looking at it from underneath or from a different angle?

- Time-consuming to create. The person authoring the 2D needs to anticipate the needs of those downstream. And even with modern 3D CAD systems, they still take considerable time to create and maintain.

3D Drawings: 2D Coupled with the Power of Interactive 3D

Imagine all of the documentation expected to be on a well-produced 2D drawing, but it is actually interactive 3D with a 3D toolset to explore.

- The annotations stay visible regardless of orientation.

- New annotations can be added.

- Semantic PMI (Product Manufacturing Information) is transferred from the originating 3D CAD system.

Here are just 3 Capabilities 3D Drawings Provide:

- Measurements: Is something not included already? The underlying Virtual Product Model is XVL and has CAD-level precision. Downstream users can add their own detail.

- PMI: Clearly see PMI annotations, including Semantic PMI (for CATIA V5, Creo Parametric, and NX ), and be able to explore the model to completely understand the PMI documentation.

- Cross-Section: If you really need to explore, dynamic cross-sections can be added by the downstream user.

In general, they are just easier to understand because they are interactive 3D.

3D Drawings

By distributing XVL 3D drawings containing PMI and other manufacturing information to downstream processes, design departments are freed from the traditional bottleneck of 2D drawing creation. Furthermore, downstream processes that do not have 3D CAD can work more efficiently with the XVL 3D drawings they receive. In addition, 3D data from each department can be reused across departments to improve the efficiency of the entire manufacturing process.

3D Snapshots

A 3D Snapshot initially looks like a 2D drawing. The author sets the initial view and captures the model in a specific state (e.g., orientation, assembled, not assembled, etc.). However, that is where the similarity ends - each 3D Snapshot is actually live interactive 3D that can be explored as a 3D Drawing.

So, if a company is transitioning from 2D drawings to 3D drawings, a logical first step would be to produce a 3D Snaphot for each 2D drawing that would normally be created. In this way, nothing is lost, but the downstream user gains much.

For example, here are 3 possible views of an engine block.

The person who authored the drawing can include all of the important information they wanted to convey in the 2D view. However, the person receiving the 3D drawing can actually explore it interactively.

Read our blog post on 3D Snapshots.

Summary

In summary, there are tremendous advantages to reducing or even eliminating 2D drawings. Leverage 3D drawings to streamline processes, improve communication, reduce errors, and ultimately enhance the overall efficiency and effectiveness of the manufacturing workflow.