Share Digital Product Data Downstream from Design

Enable Stakeholders Downstream from Design to Easily Access 3D Product Data

While in design, CAD-centric systems like PDM are best for managing product data. However, once the design is complete, the situation changes. Downstream from design, stakeholders need access to the complete product data, not a design-centric version.

What is the difference between a design-centric product view and a whole-product view? It starts with how the product is designed; this dictates how the files are organized. This may have to do with specialties, outsourced vs. in-house designed parts, task management, … the list goes on. Or maybe the CAD files are just too big. None of these reasons have any bearing on stakeholders who need to work with an entire product downstream from design.

What Functions Need 3D Data Downstream from Design?

Here are just a few:

- Manufacturing Floor: Assembly Instructions

- Tech Pubs: Manuals and other documentation

- Service Department: Service Instructions

- Part Reordering: Part Identification

Virtual Product Model

What if you could have a single digital representation of your entire product? A single representation that all stakeholders could rely upon as an accurate representation. We call this the Virtual Product Model.

What are the attributes of a Virtual Product Model?.png?width=309&name=Untitled%20design%20(22).png)

1. Complete: Includes all 3D CAD files for the complete product, regardless of the originating format (including open formats)

2. Fast: Must have reasonable performance for access on standard PCs, laptops, tablets, mobile

3. Access: Easy to use access for a wide variety of non-CAD users

4. Accurate: Stakeholders need real data for real work

The Problem

The root of the problem is the data originates in 3D CAD systems. If you are designing/manufacturing complex products, there are many designers, and lots of files – hundreds or maybe thousands, and possibly data in different 3D CAD formats.

The functions downstream from design do not care how the product was designed, they just want the entire product…the entire Virtual Product Model.

XVL for the Virtual Product Model

XVL solves these problems. XVL is:

1. CAD agnostic, supporting all major 3D CAD formats

2. Lightweight, enabling fast performance (approximately 1/100th the size of the original 3D CAD files)

3. A complete product structure has intuitive access, point and click, drag and drop

4. Accurate, even though the XVL 3D representation is ultralightweight, it retains CAD-level accuracy

Four Reasons to Use XVL for Downstream Use Cases

We will use a fictitious company called ACME, Inc. to illustrate these points.

ACME corporation is bringing a new product to market. It is a complete re-design of their very popular industrial drone.

Like many companies, ACME is distributed around the globe, including design, manufacturing, and service departments. In addition, they use subcontractors for some of the specialized components. This results in multiple 3D CAD formats being used.

Like all companies, many functions at ACME need complete product data downstream from design.

#1 - Engage a Wide Variety of Stakeholders

This is all about ease of access. Bringing a new product to market involves many departments and lots of stakeholders, such as design, manufacturing, purchasing, service, and even sales. These people are not 3D experts and certainly are not 3D CAD experts. They need a very easy and intuitive solution.

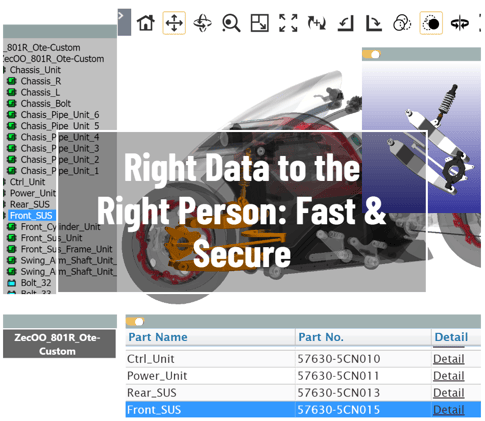

XVL Web3D Manager was designed for intuitive and easy access. It supports interactive 3D viewing and incorporates supporting data like a structured parts list, linked to the parts.

Access by stakeholders is easy. Any standard (HTML5) browser WITHOUT plug-ins is all that is needed.

ACME’s tech pub people and customer service can access the same accurate product model that manufacturing engineering uses for planning.

Also, access isn’t restricted to a web browser. The exact same virtual product model can be accessed with virtual reality.

#2 – Accuracy

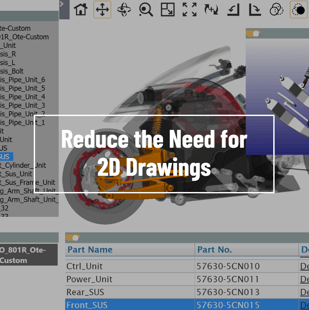

ACME knows that to truly enable their stakeholders, they must be using accurate data with the associated date, like the Bill of Materials. A “dumbed down” product version is not adequate.

For instance, a member of the service department is concerned about accessibility, including tools & part paths for replacement, the data needs to be a true virtual representation.

XVL maintains CAD-level accuracy.

#3: Performance

Access needs to be fast with using standard computers, tablets, and even phones. ACME’s stakeholders use a variety of devices, some are in the factory, while some are remote and generally, they are using standard devices not high-end engineering workstations.

Two factors enable XVL Web3D Manager to provide fast performance to stakeholders using common devices, 1) lightweight data, and 2) data streaming.

These two factors ensure fast performance regardless of the device.

#4: Avoid Wasted Time Creating and Publishing

ACME doesn’t want to waste valuable time preparing the data. They want to keep the design team focused on their value-added work.

With XVL, all 3D CAD data is automatically converted from ANY major CAD format, including open formats. This process is automatic. No additional work is required by the design team.

What about ECOs (engineering change orders)? When a design change occurs, the net changes are presented to a human to make decisions about updates to the downstream model.

Wrap Up

For ACME, the Virtual Product Model is automatically created without spending the time of people who operate the 3D CAD. This single Virtual Product Model is used by ALL downstream stakeholders using standard devices and they can even step into virtual reality with the exact same Virtual Product Model.

If you would like to explore this topic further, please click below to visit the product page and you can also experience using your own web browser with our interactive self-demos.

Click below if you would like to submit a question for your specific need.

.png)