Improve Your Designs and Manufacturability - With Robust Design Reviews

Revolutionizing Design Reviews with 3D Digital Twin Technology

In the fast-paced world of manufacturing, efficiency, cost reduction, and quality improvement are paramount. Traditional design reviews, often hampered by the need for expensive CAD licenses and high-end workstations (AND the expertise to run them), can be slow and cumbersome.

Furthermore, a 3D CAD system is not the best tool for conducting comprehensive design reviews.

This is where Lattice Technology's innovative approach using a 3D Digital Twin comes into play, transforming the design review process and driving digital transformation in the manufacturing industry.

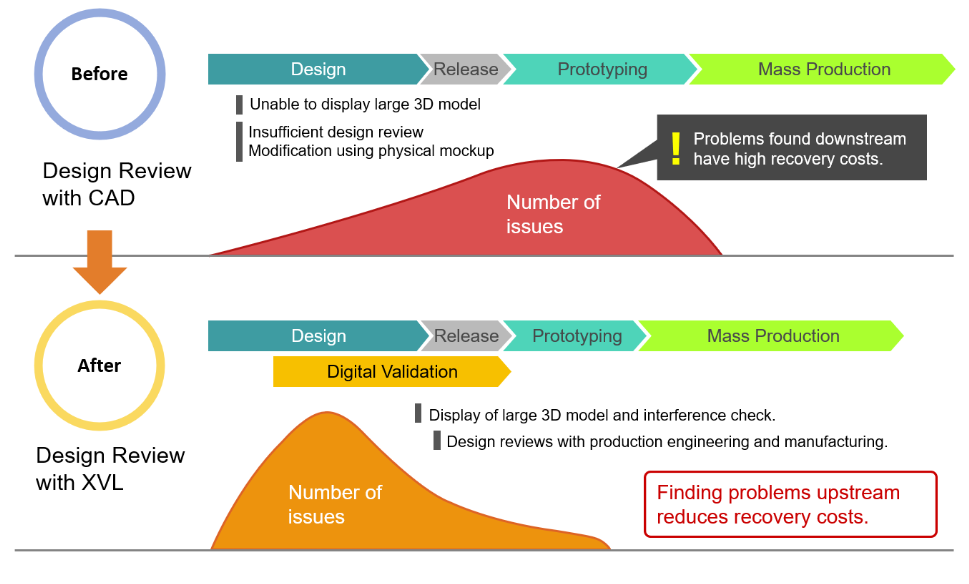

The Problem with Traditional Design Reviews

Design reviews are a critical part of the product development process, but they come with significant challenges:

- High Costs: Expensive CAD licenses and high-end workstations are required, limiting participation.

- Limited Scope: Even high-end systems struggle with large models, forcing reviews to be conducted in small sections and increasing the risk of missing issues.

- Complexity: The need for specialized knowledge to navigate CAD systems can exclude valuable input from non-technical stakeholders.

These limitations can lead to missed issues, which become more costly to fix later in the process.

The Solution: 3D Digital Twin Technology

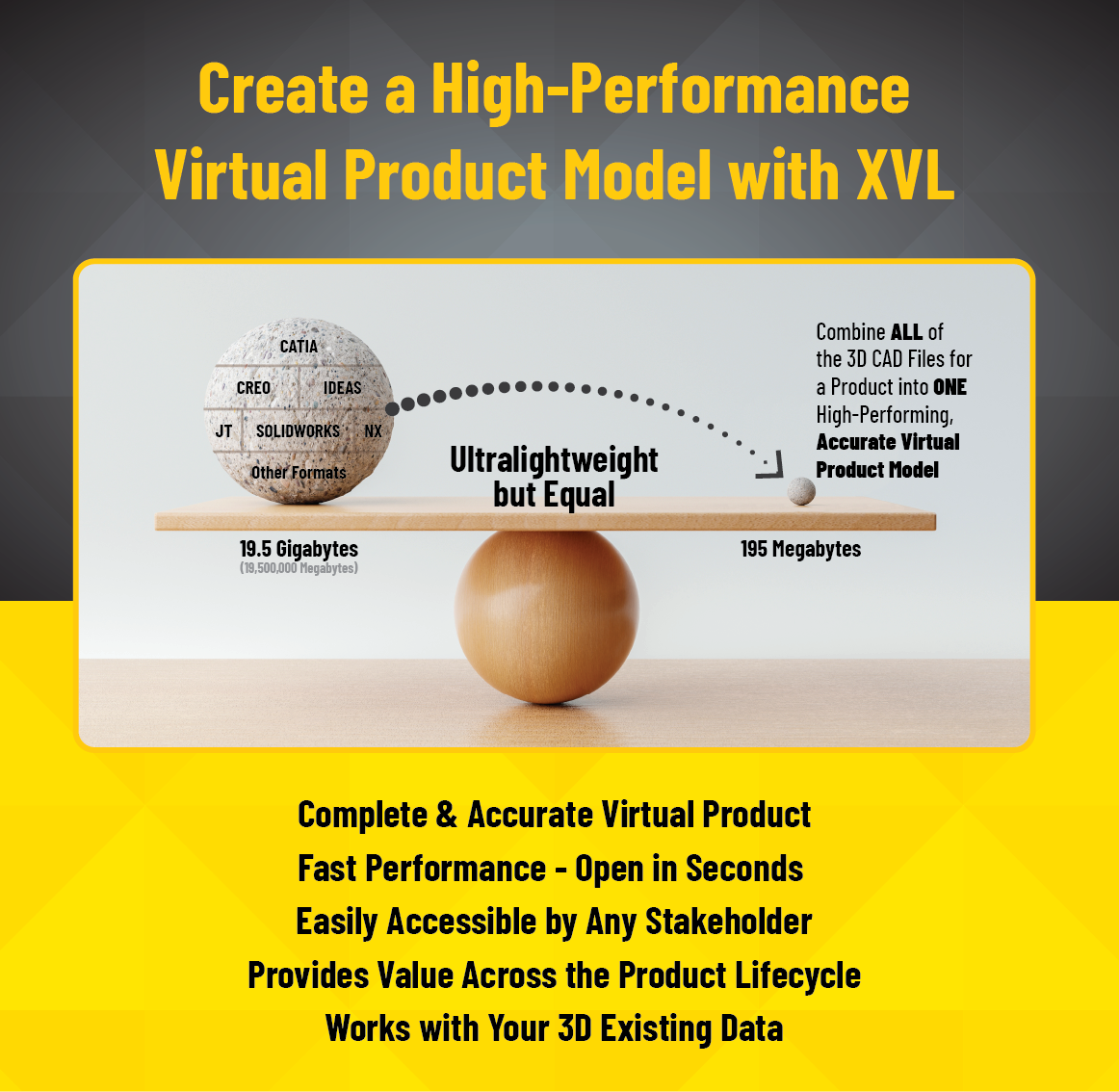

Lattice Technology's solution leverages a 3D Digital Twin to create a complete virtual product model. This approach offers several key benefits:

- Comprehensive Reviews: Perform design reviews on the entire 3D virtual product model, not just segments. This holistic view helps detect part collisions, tooling and part travel issues, and ergonomic concerns for humans and robots during assembly.

- Accessibility: The 3D Digital Twin can be viewed on standard computers, laptops, tablets, and even smartphones, making it easy to include a wide range of stakeholders in the review process.

- Accuracy and Metadata: The 3D Digital Twin retains CAD-level accuracy and includes all metadata from the originating 3D CAD system, such as Product Manufacturing Information (PMI).

Key Benefits of Lattice Technology's Design Review Solution

Fully Interactive

Lattice Technology's design review solution provides access to data similar to that available in a 3D CAD system but is much easier to use. Even non-technical people can navigate the 3D model and access all the metadata from the native 3D CAD systems.

Review the Entire Product All at Once

With Lattice Technology, you can review the entire model at once, eliminating the need to break the model into subassemblies. This comprehensive approach ensures no issues are missed due to incomplete reviews.

Cost-Effective Reviews

The software runs on standard computers, eliminating the need for high-end hardware or expensive CAD licenses. This makes it possible to perform design reviews anywhere and include participants who otherwise wouldn't have access.

Efficient Issue Detection

Automatic tools like static interference checks can review the entire model and detect hard-to-find issues between parts and assemblies. These tools display issues with color maps and cross-section views, making them easy to see, understand, and fix.

Multi-CAD Compatibility

Lattice Technology's tools can import models from any source, in any format. This allows you to build a complete model for your design reviews and find issues between systems that would be impossible to detect otherwise.

3D Tools for Interrogation

The solution includes tools for cross-sectioning, measurements, and dynamic collision detection. All review work can be saved with the model, enabling easy sharing with other stakeholders.

Issue Reporting

Generate issue reports directly from 3D models, providing clear, easy-to-understand reports in 2D and 3D. This enhances collaboration and gives designers the information they need to resolve design issues quickly.

Why XVL?

XVL technology is unique in its ability to combine all CAD files into a lightweight, accurate 3D Digital Twin. It supports all major 3D CAD formats, maintains CAD-level precision, and reduces file sizes significantly for fast performance. XVL also processes net changes between CAD versions, preserving work when engineering change orders occur.

Conclusion

Lattice Technology's 3D Digital Twin solution revolutionizes the design review process, making it more efficient, accessible, and comprehensive. By leveraging this technology, manufacturing companies can improve quality, reduce costs, and shorten time-to-market, driving digital transformation and staying ahead of the competition.

For more information on how Lattice Technology can transform your design review process, visit Lattice Technology's Digital Transformation page.

This blog post highlights the key points from the document, providing a concise and informative overview of how Lattice Technology's 3D Digital Twin solution can revolutionize design reviews in the manufacturing industry.

To learn more read our Design Review eBooklet.