What Makes XVL from Lattice Technology So Powerful?

It is our Converters!

The Foundational Difference is Unique in the Industry

Answer these questions to understand if XVL will be useful for your company:

-

How many 3D CAD files are used for your typical product designs?

-

- If the complete design of your product has 10s, 100s, or even 1,000s of 3D CAD files, XVL will definitely be beneficial.

- Do you have multiple 3D CAD formats used in the design?

- Most companies end up having parts designed in multiple CAD systems and receive CAD models from suppliers in different formats; the more formats you use, the more valuable XVL will be.

- Once a product leaves the design phase, most work should be accomplished on the complete product. Can you do that? Easily? Is it accurate, and do you have access to all of the CAD metadata (including PMI)?

- With XVL, all stakeholders can have access to the complete Virtual Product.

Combine & Convert

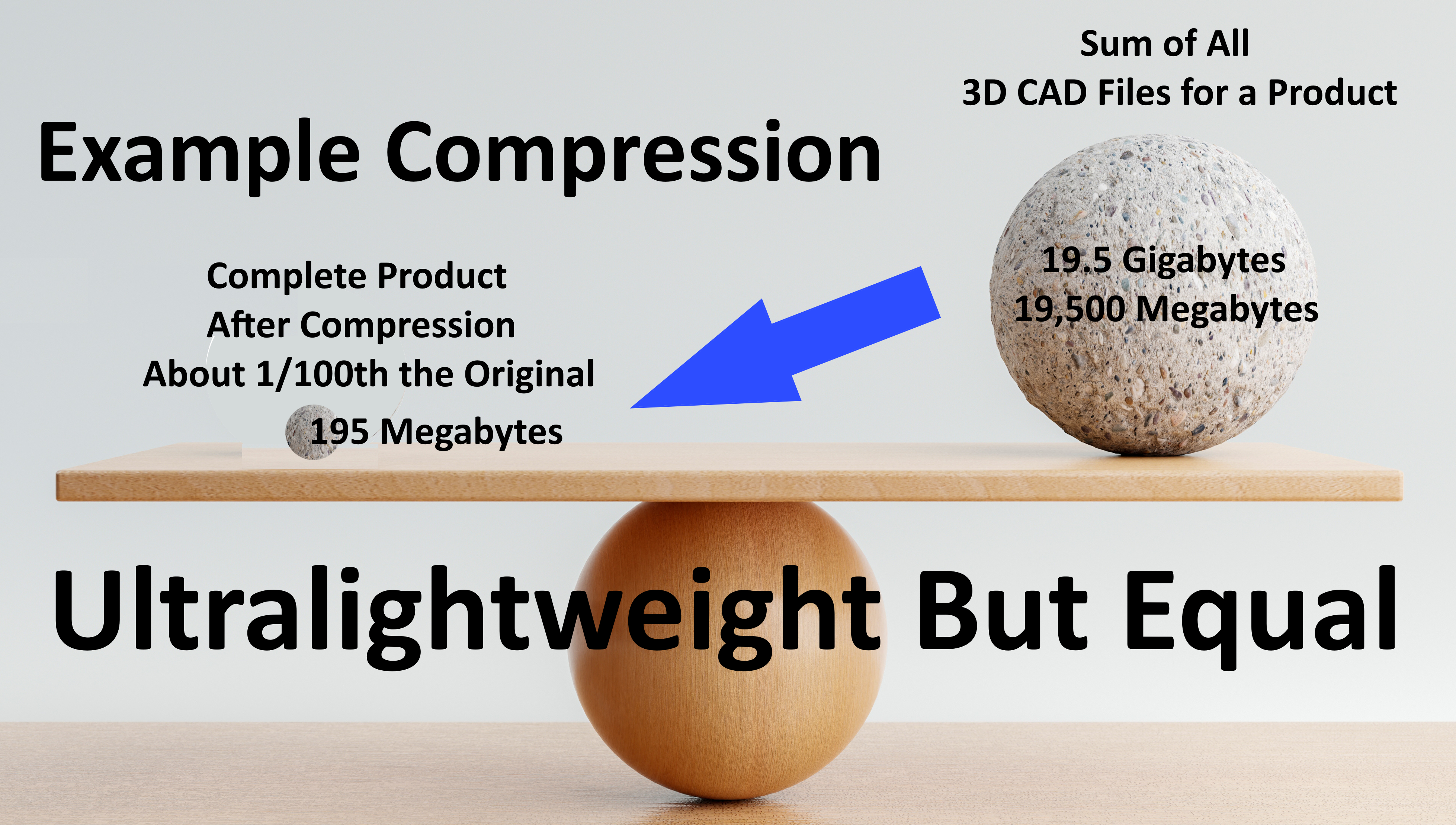

As described above, XVL can CONVERT files from any major 3D CAD system (including the CAD metadata) and combine all of these CAD files into a single Virtual Product Model. And the resulting Virtual Product Model is usually about 1% of the size of the original 3D CAD files (sometimes even smaller).

As described above, XVL can CONVERT files from any major 3D CAD system (including the CAD metadata) and combine all of these CAD files into a single Virtual Product Model. And the resulting Virtual Product Model is usually about 1% of the size of the original 3D CAD files (sometimes even smaller).

For Example

Doing the math...

- For a complete product with maybe 30 SOLIDWORKS files, 4 CREO, a couple (2) of JT, and a few (3) STEP files from vendors, averaging 500 megabytes each.

- That is 19,500 megabytes or 19.5 gigabytes - do you have a system that can load all of that heavy CAD data?

- Converting (and combining) all of these files into XVL, the total file size is just 195 megabytes - less than half the size of just one of the design files. And...this is NOT a dumbed-down representation.

So what?

This matters because now, this single, small file is the basis for performing all of your downstream operations. AND...it retains CAD-level accuracy and all of the metadata for doing real work.

Digital Transformation

Many companies are embarking on big Digital Transformation projects.

We think the first step for the manufacturing company is to make better use of the digital assets you already have, which is the lifeblood of your company -- product design data.

We have been helping companies for a long, long time to do this...well before Digital Transformation was a thing.

Downstream (from Product Design) Use Cases

- How do you conduct design reviews?

- Do you have a solution that makes it easy to engage stakeholders…even those who are not computer savvy? Think of the person working on your manufacturing floor; how do you get their input?

- With XVL, it is easy, and there are many ways. One way is a 3D Snapshot where a specific view of a model can be captured and then annotated. By the way, the original PMI is also included, and saved. The person receiving the 3D Snapshot can easily view everything, and even better, they receive a live 3D version that can be examined (rotate, zoom, measure, section, and much more).

- Can you virtually plan and then simulate/validate your manufacturing assembly process?

- This is very difficult to do. There are some very expensive solutions but most companies are not using these.

- With XVL, because the complete Virtual Product Model is available, the entire manufacturing process can be planned and simulated virtually. And, after the manufacturing plan is complete with XVL, this becomes the basis for creating the interactive assembly work instructions.

- How do you create technical documentation?

- Most companies use a lot of screenshots and even pictures and do a lot of writing.

- Using XVL, this process will be dramatically easier, and the results will be better. Your Tech Pubs department will be able to have the complete Virtual Product Model as their basis

- How do you author and publish service procedures?

- More screenshots, photos and writing?

- With XVL, all of the work that was performed for manufacturing planning can be leveraged into Service Instructions. Drag 'n Drop. Add annotations. Deploy interactive Service Instructions.

The above use cases are some of the many ways that XVL can help the modern manufacturing company.

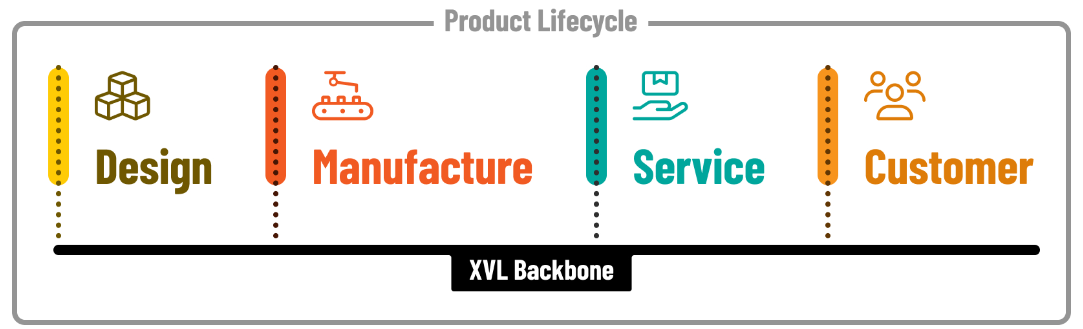

Why 3D CAD Data Conversion is the Foundation

It is all about the data and empowering stakeholders to perform their jobs better and faster :

- Think of XVL as an extension of your 3D CAD system/s.

- All of your files, even in different formats, can be combined into one.

- CAD-level accuracy is maintained in this new Virtual Product Model.

- This complete Virtual Product Model stays connected to the native CAD, so when a change (ECO) occurs, the Virtual Product Model is updated.

- All of the processes that are based on the product data can now use this single master.

Native 3D CAD

There are many 3D CAD viewers available. XVL is not just a simple viewer.

Multiple 3D CAD files (even of different formats) are converted into a single XVL file - we call this the Virtual Product Model. The following formats can be converted directly without using a neutral format.

Supported 3D Formats

- Creo Elements/Direct Modeling

- Creo Parametric

- DXF/DWG (Polygon)

- NX I-deas

- IGES

- Industry Foundation Classes

- JT

- NX

- OBJ (Polygon)

- Parasolid

- PRC

- Solid Edge

- SOLIDWORKS

- STEP

- STL

- U3D

- WRL (VRML2)

Want to Learn More?