Manufacturers: Increase Your Competitiveness by Increasing Efficiency Across Departments

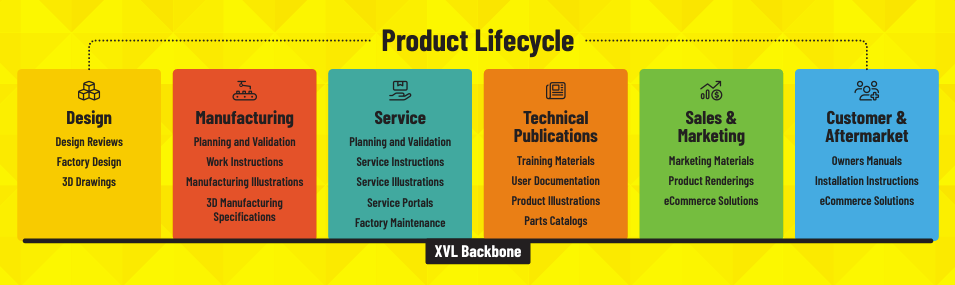

In today's competitive manufacturing industry, companies are constantly seeking ways to improve efficiency, reduce costs, and shorten time to market. One area that is ripe with opportunity for making better use of your 3D design data across the product lifecycle.

XVL can do this.

XVL is a technology that is CAD-agnostic and extends the value of 3D CAD across the product lifecycle. Native 3D CAD files are converted into XVL where all of the metadata is passed and CAD-level accuracy is retained. Unlike expensive CAD licenses, access is free and easy for stakeholders who need the data.

In this blog post, we will explore the benefits of XVL technology, with a primary focus on its performance and the ability to combine multiple 3D CAD files into one virtual product, even in different formats.

Lightweight and Versatile 3D Data

3D CAD files can be large and cumbersome, making it challenging to share and access them across departments. And 3D CAD is difficult to use, and the licenses are expensive.

3D CAD files can be large and cumbersome, making it challenging to share and access them across departments. And 3D CAD is difficult to use, and the licenses are expensive.

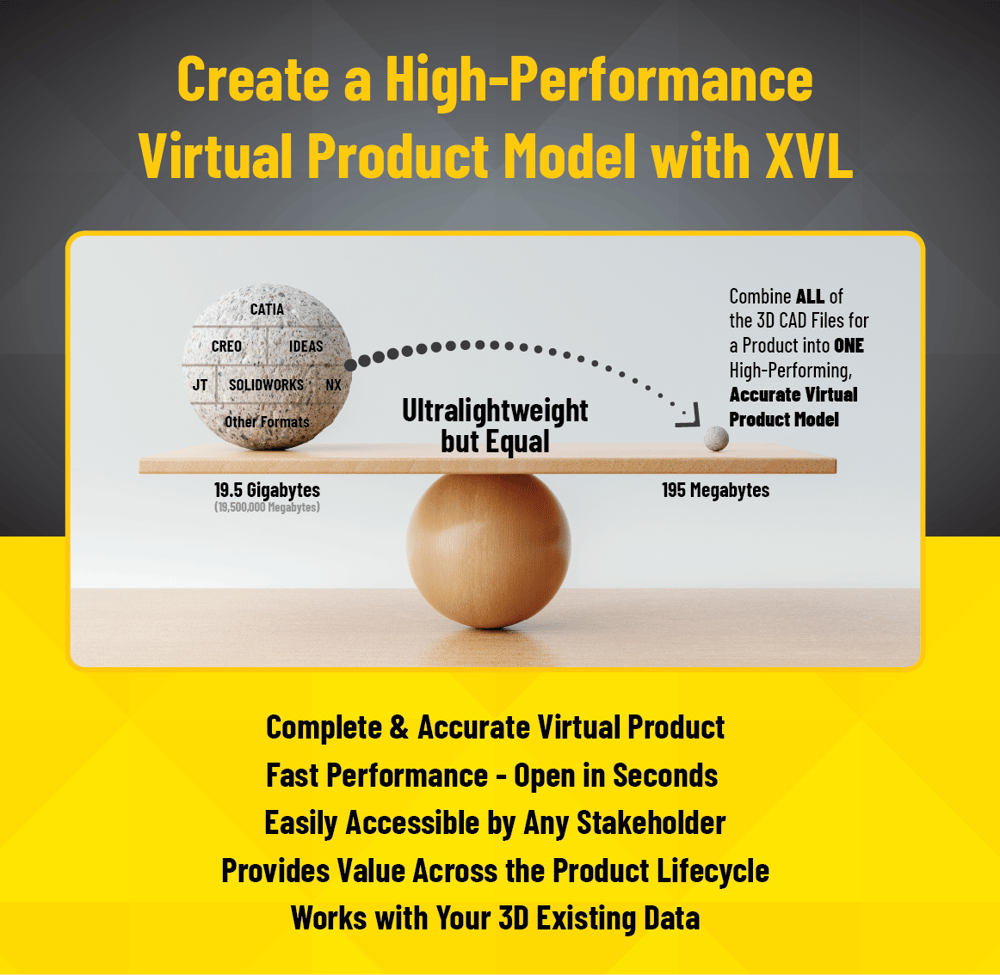

XVL addresses this issue by providing lightweight 3D models that are significantly smaller in size (about 1/100th the size) compared to the original CAD files. This lightweight nature of XVL allows for fast performance and they can be accessed for FREE using only a standard web browser, making it possible to be used by anyone. This enables seamless distribution of 3D models to various stakeholders, including tech pubs, manufacturing planning, service, suppliers, quality control…and the list goes on, without the need for expensive licenses or high-spec computers.

Combining Multiple 3D CAD Files

Manufacturing companies often use multiple CAD systems for different aspects of their product design. This can lead to challenges when it comes to integrating and collaborating on designs. XVL technology overcomes this hurdle by enabling the combination of multiple 3D CAD files into one virtual model, even if they are in different formats. For example, CAD files from CATIA, SOLIDWORKS, NX, and others can be seamlessly integrated into a unified 3D model using XVL. This allows stakeholders from different departments to work with the entire product to verify the design and functionality of complex products, ensuring that all aspects of the product are considered during the design process.

Streamlined Collaboration and Communication

With XVL's ability to combine multiple 3D CAD files, collaboration and communication between departments become more streamlined and efficient. Instead of relying on separate CAD systems and struggling with file compatibility issues, teams can work together seamlessly on a single virtual product. This eliminates the need for time-consuming and error-prone data translations or conversions. Manufacturing managers can now ensure that all stakeholders have access to the most up-to-date and accurate design information, enabling effective communication and reducing the risk of misinterpretation or errors.

With XVL's ability to combine multiple 3D CAD files, collaboration and communication between departments become more streamlined and efficient. Instead of relying on separate CAD systems and struggling with file compatibility issues, teams can work together seamlessly on a single virtual product. This eliminates the need for time-consuming and error-prone data translations or conversions. Manufacturing managers can now ensure that all stakeholders have access to the most up-to-date and accurate design information, enabling effective communication and reducing the risk of misinterpretation or errors.

Improved Design Quality and Faster Iterations

By utilizing XVL's lightweight and versatile 3D models, manufacturing managers can enhance the quality of their designs and accelerate the iteration process. With the ability to share and access 3D models easily, engineers can perform virtual tests and analyses, identifying potential design flaws or improvements early in the process. This reduces the reliance on physical prototypes, saving time and resources. Faster iterations also mean that design improvements can be implemented swiftly, leading to shorter development cycles and faster time to market.

By utilizing XVL's lightweight and versatile 3D models, manufacturing managers can enhance the quality of their designs and accelerate the iteration process. With the ability to share and access 3D models easily, engineers can perform virtual tests and analyses, identifying potential design flaws or improvements early in the process. This reduces the reliance on physical prototypes, saving time and resources. Faster iterations also mean that design improvements can be implemented swiftly, leading to shorter development cycles and faster time to market.

With or Without PDM/PLM

PDM and PLM systems are very good at managing data. They are also very design-centric. This is contrasted with XVL, which is product-centric. With XVL, it does not matter how a product is designed, how many files are used or even what systems were used - it is simply one virtual product. Does the manufacturing planner or Tech Pubs person care about the files that were used to make the design? No, they just want fast and easy access to the complete virtual product.

XVL does have version control. For some companies, this is enough. Other companies will still opt for design data management to be contained in PDM/PLM systems. However, for sharing outside of the design department, XVL is the logical choice.

Conclusion

XVL technology offers a powerful solution to maximize efficiency and collaboration in the design and manufacturing process. Its lightweight nature and the ability to combine multiple 3D CAD files into one virtual product, even if they are in different formats, revolutionize the way teams work together. With XVL, manufacturing companies can streamline collaboration, improve design quality, reduce costs, and shorten time to market. By embracing XVL technology, manufacturing managers can unlock the full potential of their design assets and gain a competitive edge in the market.

Learn More

Get our eBook that provides managers in manufacturing companies with insights into the applications and benefits of using 3D CAD data in manufacturing.

It showcases real-world examples of companies successfully leveraging lightweight 3D solutions to increase manufacturing throughput while improving quality in various aspects of the manufacturing process.