Four Essentials of Effective Work Instructions

I recently came across the following post that I thought might be useful for people thinking about introducing assembly/manufacturing work instructions to their organizations or refining how work instructions are currently used. The author makes some excellent points. His point about keeping in mind the intended audience of the work instruction is particularly interesting.

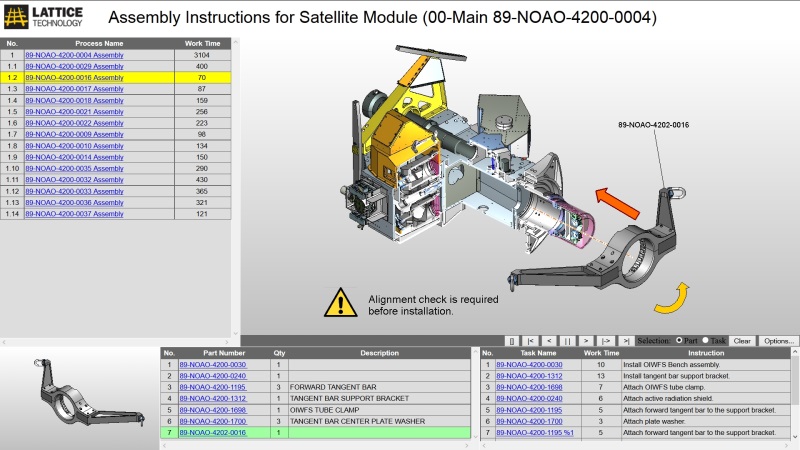

At Lattice Technology, we provide an easy-to-use authoring tool (for non-technical users) to create work instructions.

At Lattice Technology, we provide an easy-to-use authoring tool (for non-technical users) to create work instructions.

Perhaps more important than authoring, are the options for consuming and using the work instructions. If the solution doesn't help the worker perform his/her job or it’s not convenient, it simply won't be used — or at least, it won’t be used to the level intended.

Options for Viewing Interactive Assembly Work Instructions

We provide many electronic options for consumption, including the following: (Yes, of course, they can be printed too.)

- 3D PDF

- HTML Web Pages

- Microsoft Excel ®

- Standalone Application

- Web-base Application

All of these offer interactive 3D and are FREE to consumers (click here to get more information):

The following was originally posted at http://explainers.com/Articles/Four-Essentials-Effective-Work-Instructions.htm.

Four Essentials of Effective Work Instructions

Overview: Returning the Focus to the Worker

A work instruction is a tool provided to help someone to do a job correctly. This simple statement implies that the purpose of the work instruction is quality and that the target user is the worker. Unfortunately, in many workplaces, today’s work instructions have little connection with this fundamental focus. Factories have encumbered work instructions with content that has been added to satisfy auditors, lawyers, engineers, accountants and yes, even quality managers. We’ve piled on so much extraneous material that we’ve lost sight of the intended purpose of work instructions.

Instead of providing a simple tool to do a job right, we’ve buried the work instruction under a cascade of specifications, contract requirements, revision history, references, controls, licensing provisions and engineering theory. The person who uses the work instruction has become an afterthought in favor of satisfying a licensing or certifying auditor.

If work instructions are to be practical quality tools, the worker must at least share focus with the auditor. This shift in emphasis does not require removal of the licensing and certification information that has been added to instructions. However, the procedure portion of the work instructions can be improved, often significantly, by appropriate consideration of the worker. Workers learn quickly to spot the usable portions of the work instructions and apply the appropriate material on the job.

This paper suggests a four-part criteria against which work instructions can be evaluated and improved as needed. As a first step in judging the overall effectiveness of work instructions, managers can examine their work instructions against four essential characteristics: credible, usable, accessible and consistent.

Credible: Workers Trust Them

Credible work instructions are at the heart of standardized best practices. In a workplace that’s committed to one and only one way to perform all procedures and processes, work instructions must define that standard.

When work instructions are credible, workers accept and trust them. But it’s easy for work instructions to lose their credibility. A common way to lose credibility is when standard procedure updates and changes get passed on verbally and there are consistent and regular delays in updating the written work instructions. With verbal changes, something can be missed or an individual can otherwise fail to get the correct message. In a busy workplace with frequent undocumented changes and updates, work instructions become marginalized with workers no longer trusting them as being accurate.

Work instructions also lose credibility when a supervisor initiates a change and deviates from standardized best practice. Even though the change may be an improvement, the worker is forced to make a choice, and the boss’s words are always going to win over the written work instructions. For work instructions to be credible, workers must believe that they define the one, single, proper way to perform a task.

[A factory that makes frequent work document revisions could have a flawed system. See Revising Work Documents for perspectives on work instruction revision cycles.]

Clear: Workers Understand Them

A clear work instruction can be quickly understood by the worker with a minimum of effort. To accommodate the typical worker, an ideal work instruction explains mostly with graphics using only minimal clarifying text. Illustrations or other graphic support should be immediately visible and the worker should not being required to go to any other location for supporting information.

Work instructions start to become unusable when they contain extraneous matter not directly related to the procedure. Also, multi-page or multi-screen work instructions that cannot be quickly and easily grasped do not meet the clarity test. Because most workers have neither the time nor the patience to struggle with unclear work instructions, they lose their practical value.

Accessible: Workers Can Get To Them

Work instructions are accessible when they can be located quickly and easily. "Quickly" means within seconds and "easily" requires a retrieval system that the worker knows, understands and trusts. An ideally accessible work instruction is displayed as a job aid in immediate full view in the workspace.

If someone with a question about the proper procedure must struggle to even locate the applicable work instruction, the typical worker will find an alternative such as trial and error, guesswork, and questioning an associate or supervisor. While these alternatives might produce the right answer, they lead to a decline in the significance and importance of the work instructions.

Consistent: They Match Worker Training

Consistent work instructions conform to a style guide developed specifically for procedures and work instructions. There must be rigid consistency of terminology so that the same word means the same thing every time. There can be no undefined acronyms and confusing technical terms. All instructions should follow the same format so that the user always knows where to find information such as required tools or control settings.

Consistent work instructions also demand that the material used for worker training is consistent with provided job aids.

Conclusion

In the absence of effective user-focused work instructions, we force the worker to employ a host of unsatisfactory alternatives including guesswork, trial and error, rumor, and tribal knowledge information transfer. The inevitable result is variation, deviation, reduced productivity and lost potential.

To achieve the desired quality benefits of standard best practice, effective work instructions need to be a fundamental first step.

Some References

Chabrow, E. 2001. Uncomplicating IT: Simpler Said Than Done. Information Week (April) 45–48.

Mayer, C. 2002. Why Won’t We Read the Manual? Washington Post Sunday (May) H01.

Ricadela, A. 2001. Remember the User’s Point of View. Information Week (April) 48–56.

Rooney, J. 2002. Reduce Human Error. Quality Progress 35 (September) 27–35.

Sweeney, P 2003. Developing Work Instructions for Aliterate Users. American Society for Quality