3D as a Platform for Digital Transformation

If a picture is worth a thousand words, then how many pictures is a 3D model worth? The answer is plenty if the 3D is accurate, lightweight, and easy to use. By adopting lightweight 3D as the backbone of their data pipeline, manufacturing companies worldwide are transforming their businesses. To understand, it is necessary to understand the difference between digitalization and digital transformation.

Digitalization vs. Digital Transformation

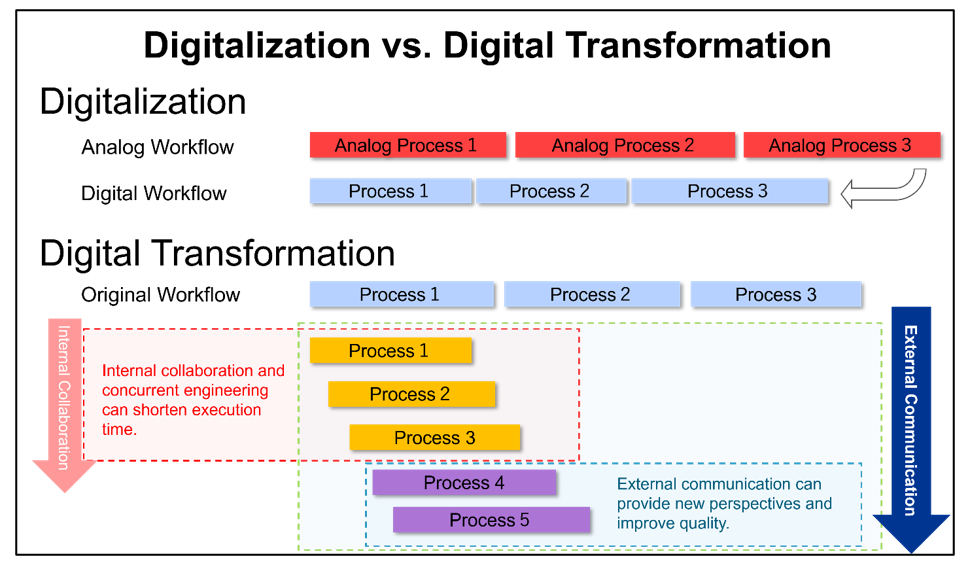

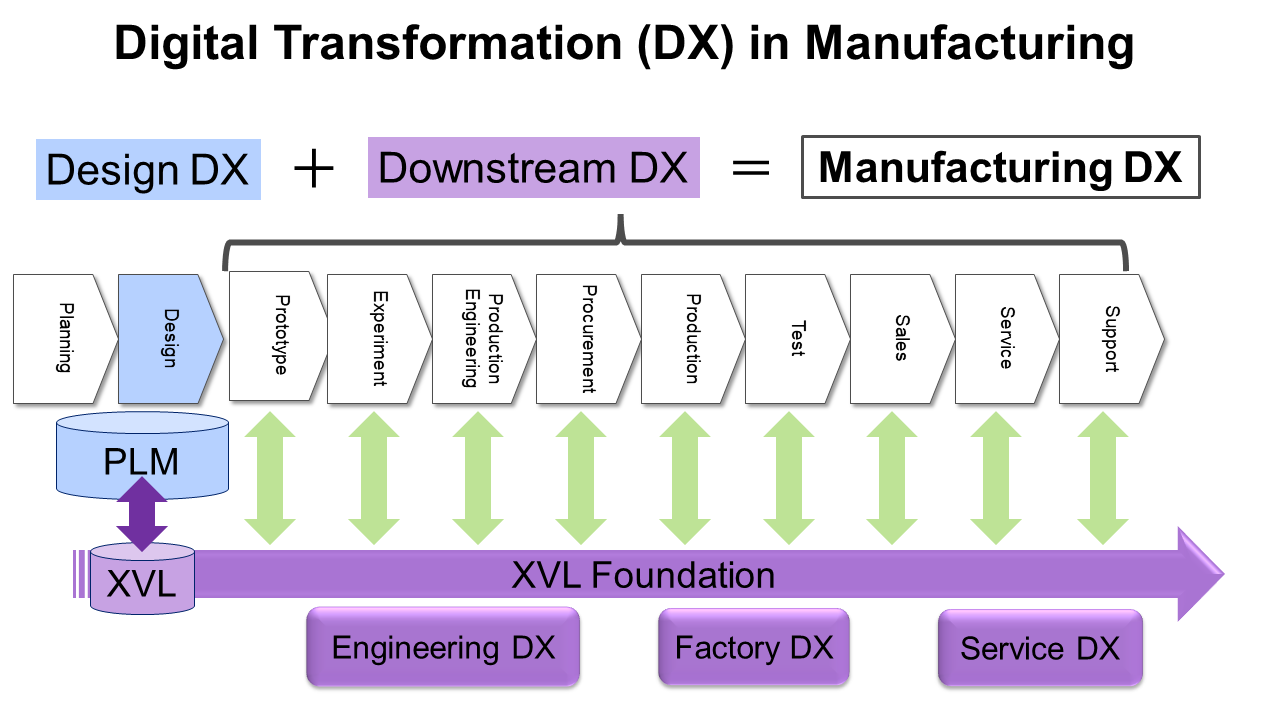

Digitalization refers to introducing digital tools to replace inefficient analog or manual processes. It can bring significant performance improvements. Digital transformation goes further. It involves using the power of IT not just to improve the efficiency of existing processes but to fundamentally change how work is done.

Digital transformation enables the parallelization of business processes that were previously connected in series, enabling concurrent processes. Concurrent processes can dramatically shorten delivery times while reducing costs and improving quality.

Digital transformation enables rethinking current business processes. It opens the door to bringing in new stakeholders and fresh perspectives to improve quality and further innovate processes.

Casual3D

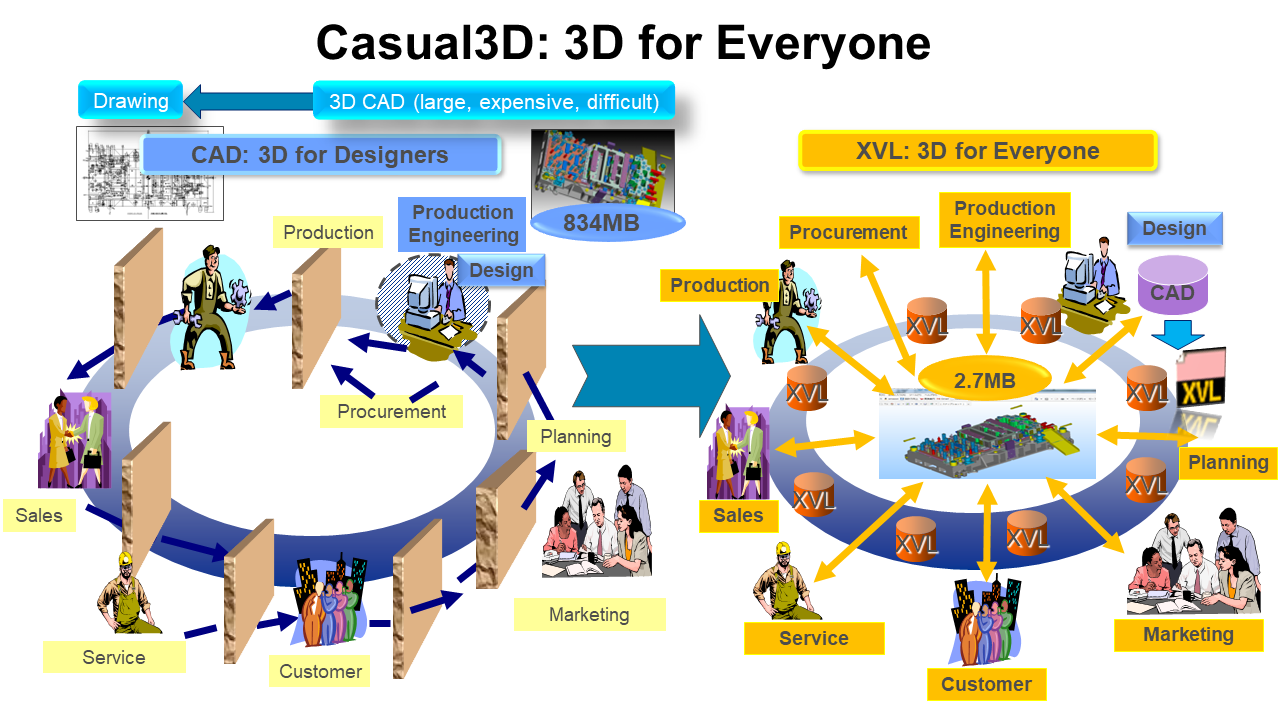

"Casual3D" is a term coined by Lattice Technology. It means making 3D data usable "anywhere, anytime, by anyone." Typically, only a small fraction of a company's employees, generally in the design department, have access to expensive and difficult-to-use 3D CAD software. This means that the remaining employees never see or use 3D data, even though the organization invests a significant amount of time, education, and resources to create it.

The figure above was created in the early 2000s to describe the concept of Casual3D. At that time, 3D CAD data was too heavy and difficult to use outside the design department, so paper drawings created from 3D CAD data were used in the field. This created barriers between departments and hindered process transformation.

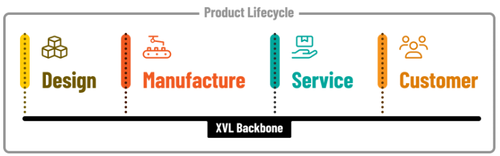

To overcome these barriers, Lattice Technology developed the XVL format. XVL can reduce the size of engineering 3D data to about 1/100 of the original while maintaining a high level of precision. The following capabilities make XVL a uniquely suitable platform for Digital Transformation.

- Performance. The CAD model of a complete complex product can be enormous, XVL delivers performance.

- Richness. XVL has a rich data structure that can handle all associated product data, from part information and metadata to multiple bills of material to data collected from IoT devices.

- Compatibility. XVL-based solutions integrate with other systems, including 3D CAD, PLM, ERP, and MES.

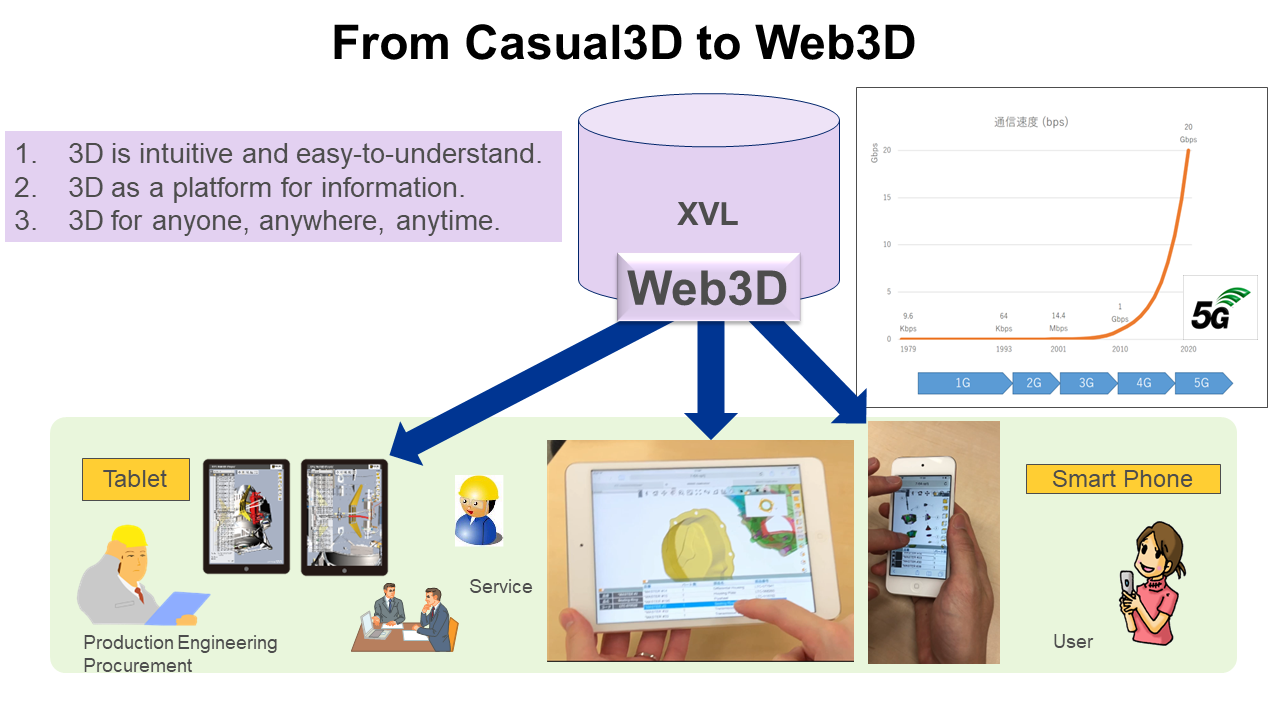

From Casual3D to Web3D

Fast forward to today. The advent of broadband internet and gigabit mobile networks has dramatically expanded the number of potential 3D users. This technology is changing the way sales and service departments do business and providing the benefits of intuitive, easy-to-use 3D content to new groups of users. With this in mind, Lattice Technology has developed a Web3D solution to deliver and display large 3D models on mobile devices. This system lets mobile users browse 3D drawings, instructions, parts catalogs, and service manuals on their mobile devices.

Accelerating Digital Transformation

XVL provides a solid foundation for digital transformation. As the application area of lightweight 3D based on design information expands, it is widely recognized that 3D models, which were once only accessible to highly trained engineers, can be utilized by the entire organization. Having easily accessible accurate 3D data available enables inter-company teams to use it, even with related companies and with customers. This is the most significant advantage of standardizing on the XVL format. When 3D is universally available, there's no limit to the innovations that are possible; there's no limit to the possible innovations.

XVL has enabled manufacturers to evolve their business processes. As XVL is established inside an organization, the value of 3D data increases, and XVL becomes the foundation for achieving digital transformation.

Looking forward, Web3D technology can potentially change how businesses operate. This technology allows manufacturers to provide clear and easy-to-understand 3D data to their customers, partners, and supply chain. By using Web3D, businesses can transform their digital capabilities and become more efficient in the industry they operate in.

Learn More

Visit this webpage to learn more about Lattice Technology's solutions for Digital Transformation for the manufacturing company.