Mfg Companies: 5 Ways to Boost Efficiency by Sharing 3D Product Info Downstream from Product Development

Discover how better utilization of 3D product information can revolutionize efficiency in manufacturing companies.

Improved Visual Representation for Effective Communication

.jpeg?width=400&height=269&name=3D%20Product%20Visulation%20for%20Downstream%20Stakeholders%20(1).jpeg) One of the key benefits of easily sharing 3D product information with stakeholders downstream from product design, including manufacturing, technical publications, and service, is the improved visual representation for effective communication. With 3D product information, stakeholders can visualize the product in a more realistic and detailed manner, allowing for better understanding and communication of design intent. This enhanced visual representation enables clearer communication between different teams and departments, reducing the chances of misinterpretation or confusion.

One of the key benefits of easily sharing 3D product information with stakeholders downstream from product design, including manufacturing, technical publications, and service, is the improved visual representation for effective communication. With 3D product information, stakeholders can visualize the product in a more realistic and detailed manner, allowing for better understanding and communication of design intent. This enhanced visual representation enables clearer communication between different teams and departments, reducing the chances of misinterpretation or confusion.

Furthermore, the use of 3D visualizations can facilitate effective communication with non-technical stakeholders such as management. By presenting product information in a visually appealing and easily understandable format, 3D visualizations can help management grasp the key aspects of the product design and make informed decisions more efficiently.

Enhanced Operational Efficiency in Production

Sharing 3D product information downstream from product design can greatly enhance operational efficiency in production. By providing stakeholders with accurate and detailed 3D models, manufacturing companies can streamline their manufacturing processes and reduce errors and delays. With 3D product information, production teams can gain a comprehensive understanding of the product's design, assembly, and manufacturing requirements, enabling them to optimize their workflow and minimize inefficiencies.

Sharing 3D product information downstream from product design can greatly enhance operational efficiency in production. By providing stakeholders with accurate and detailed 3D models, manufacturing companies can streamline their manufacturing processes and reduce errors and delays. With 3D product information, production teams can gain a comprehensive understanding of the product's design, assembly, and manufacturing requirements, enabling them to optimize their workflow and minimize inefficiencies.

Additionally, 3D product information allows for the virtual simulation of manufacturing processes, enabling companies to identify potential bottlenecks or issues before they arise in the actual production environment. This proactive approach can save time and resources, leading to improved operational efficiency and cost-effectiveness.

Reduced Mistakes and Revisions

One of the major advantages of easily sharing 3D product information with stakeholders downstream from product design is the significant reduction in mistakes. With 3D product information, all stakeholders have access to accurate and up-to-date information, reducing the chances of misinterpretation or errors in the manufacturing process.

One of the major advantages of easily sharing 3D product information with stakeholders downstream from product design is the significant reduction in mistakes. With 3D product information, all stakeholders have access to accurate and up-to-date information, reducing the chances of misinterpretation or errors in the manufacturing process.

Making a 3D visual representation of the product accessible to stakeholders aids in identifing potential issues or discrepancies early on, minimizing the need for costly revisions or rework.The ability to detect and address design flaws or manufacturing challenges before they become problems can result in substantial time and cost savings for manufacturing companies.

Faster Time-to-Market

Sharing 3D product information downstream from product design can significantly contribute to faster time-to-market for manufacturing companies. By providing stakeholders with detailed and accurate 3D models, companies can expedite the entire product development and manufacturing process.

Sharing 3D product information downstream from product design can significantly contribute to faster time-to-market for manufacturing companies. By providing stakeholders with detailed and accurate 3D models, companies can expedite the entire product development and manufacturing process.

With 3D product information, teams can collaborate more efficiently, as they have access to the same visual representation of the product design. This reduces the time spent on clarifications and iterations, allowing companies to accelerate their product development timeline. Additionally, the use of 3D visualizations can facilitate faster decision-making, as stakeholders can easily understand and evaluate the design options and make informed choices without the need for physical prototypes or lengthy discussions.

Improved Customer Satisfaction and Service

By providing accurate and realistic 3D representations of the product, companies can effectively communicate the features, functionalities, and benefits to customers, setting clear expectations and building trust.

By providing accurate and realistic 3D representations of the product, companies can effectively communicate the features, functionalities, and benefits to customers, setting clear expectations and building trust.

Additionally, 3D product information can be utilized in technical publications and service documentation, enabling customers to easily understand and troubleshoot product issues. This can result in improved customer self-service capabilities and reduced support calls. Furthermore, accurate 3D product information can also be utilized in training materials for service technicians, enhancing their ability to diagnose and resolve issues efficiently, leading to improved customer service and satisfaction.

Why XVL is the Best Way to Do This

3D CAD is great for the design department, but not for the rest of the company.

XVL takes off from where your 3D CAD leaves off.

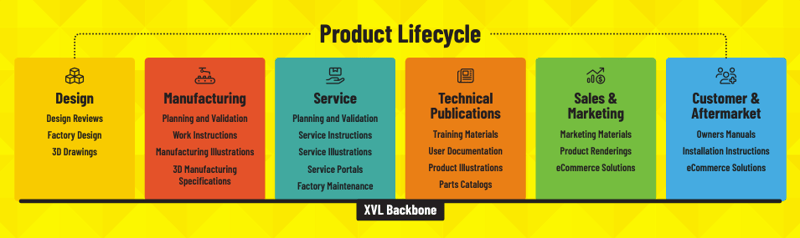

Complete Virtual Product to Support the Complete Product Life Cycle

With XVL, any stakeholder throughout the product lifecycle can access the complete virtual product with intuitive and easy access. You probably have a PLM or PDM system that contains the design data, but it is easy and intuitive for stakeholders to access.

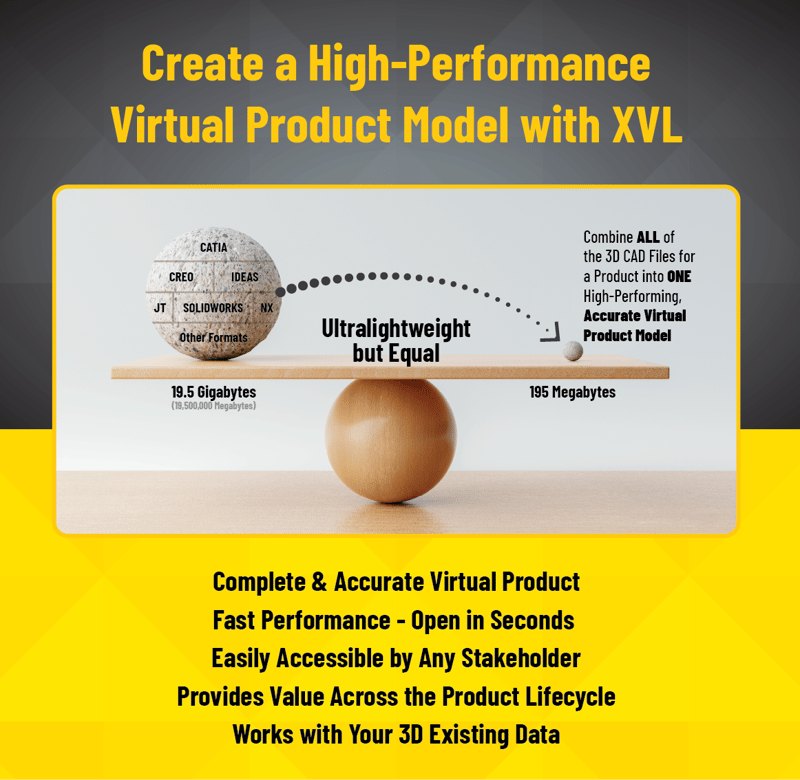

XVL Provides Complete Data and Fast Performance

With XVL, all 3D CAD data (even different formats) is combined into a SINGLE Virtual Product Model. XVL retains CAD-level precision and all metadata from the originating CAD system.

And with XVL, function-specific information can be added (for example assembly work instructions and service instructions).

And data can be pulled from XVL for example to create technical illustrations.

.jpeg)