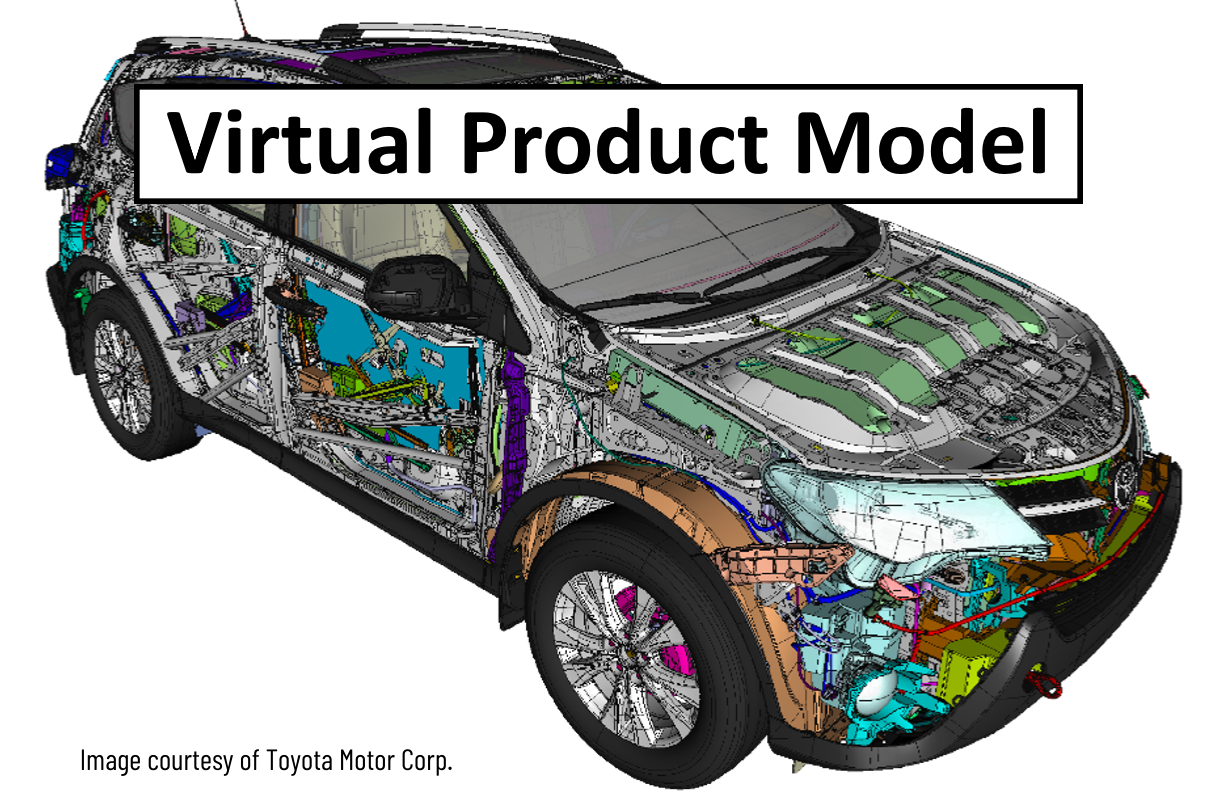

The Virtual Product Model - Enable ANY Stakeholder Easy Access to Product Data

What is a VIRTUAL PRODUCT MODEL?

The notion of a VIRTUAL PRODUCT MODEL encompasses more than just the existence of 3D CAD files representing the parts and assemblies of a product. While many companies may think they have a VIRTUAL PRODUCT MODEL because all parts are in 3D CAD, the accessibility and usability of this data by stakeholders beyond the design department are crucial factors in determining its effectiveness.

Challenges When Using a 3D CAD System

A true VIRTUAL PRODUCT MODEL should be accessible and usable by individuals outside the design department, including stakeholders such as manufacturing teams, suppliers, marketing personnel, and even customers. However, several challenges hinder the achievement of this ideal:

- Accessibility: 3D CAD files tend to be large, and the complexity of products often results in the creation of numerous files. Moreover, different teams may use various CAD systems, leading to compatibility issues. Accessing and efficiently navigating through these files can be challenging, especially for individuals without CAD experience or specialized software licenses.

- Data Heterogeneity: Products often incorporate components and subassemblies sourced from different suppliers, each providing design data in various formats. All of these files must be combined regardless of their format and resorting to “dumbed down” open standard formats is not a great solution as a lot of data is lost.

- Extremely Large CAD File Sizes: Complex products can consist of hundreds or even thousands of CAD files, collectively amounting to gigabytes of data. Managing and processing such vast amounts of heterogeneous data presents significant challenges.

To truly embody a VIRTUAL PRODUCT MODEL, a system must overcome these challenges. It should enable easy access to the complete product model, including all parts and subassemblies, regardless of file format or source. Furthermore, it should facilitate collaboration and communication among diverse stakeholders by providing intuitive interfaces and tools that do not require specialized skills or software licenses.

Merely having 3D CAD files does not constitute a VIRTUAL PRODUCT MODEL. The accessibility, usability, and comprehensiveness of the product data across various stakeholders are essential criteria for assessing the effectiveness of a VIRTUAL PRODUCT MODEL.

Continue reading to learn about how XVL can provide a true VIRTUAL PRODUCT MODEL with high fidelity and including all of the data and metadata from the authoring 3D CAD system.

Attributes of a VIRTUAL PRODUCT MODEL

A robust VIRTUAL PRODUCT MODEL embodies several key attributes essential for enhancing manufacturing efficiency:

- Complete and Accurate Graphical Representation: The model should provide a comprehensive and precise visual depiction of the product, encompassing all its constituent parts and subassemblies. This ensures that stakeholders have a clear understanding of the product's composition and structure.

- Hierarchical Part Structure with Multiple Bills of Material (BOM): A well-structured VIRTUAL PRODUCT MODER should incorporate a hierarchical organization of parts and assemblies, accompanied by multiple Bills of Material (BOMs). These include engineering (eBOM), manufacturing (mBOM), and service (sBOM) BOMs, catering to diverse downstream use cases. This hierarchical structure facilitates efficient management and tracking of components throughout the product lifecycle.

- CAD Independence: An ideal VIRTUAL PRODUCT MODER should not be reliant on CAD software or expertise. Users should be able to navigate and interact with the model without the need for CAD experience or licenses. This democratizes access to crucial product information, empowering a broader range of stakeholders to engage with the model effectively.

- Optimized Performance for Standard Computers: The model should exhibit robust performance, enabling fast and intuitive interactions on standard computing platforms. Smooth navigation and quick data retrieval are essential for facilitating seamless collaboration and decision-making across various departments.

In essence, the VIRTUAL PRODUCT MODER serves as a visual, easily accessible, and comprehensive repository of product information. While it caters to the needs of the design department, its primary purpose is to support downstream functions that can leverage readily available, accurate, and detailed product data to enhance operational efficiency and effectiveness.

VIRTUAL PRODUCT MODEL Use Cases

These are just some of the use cases for a VIRTUAL PRODUCT MODEL.

Production Engineering

The Production Engineering team plays a critical role in the manufacturing process, responsible for creating efficient methods to build products. They don't care or need to know how a product was designed. They just have to figure out how to make it.

Having access to a complete VIRTUAL PRODUCT MODEL that is comprehensive, accurate, and easily navigable greatly increases their ability to develop manufacturing processes that are efficient.

Visualization and Analysis

Production teams need to review the procedures with an eye towards productivity and safety. These reviews include:

- Assembly Review: Verify that the product can be assembled correctly per the procedure.

- Workability Review: Verify that the work can be performed safely and comfortably.

The VIRTUAL PRODUCT MODEL enables you to run assembly simulations and analyze the production plan in detail that is not possible with CAD data.

Technical Communications

Authoring good documentation is challenging. Often companies will resort to pictures of prototypes, screenshots from the CAD system, or even producing drawings by hand using a general-purpose drawing program.

Using a VIRTUAL PRODUCT MODEL, the technical illustrator has access to the complete product in interactive 3D. They can easily position the parts to produce optimal 2D illustrations. They can even use the VIRTUAL PRODUCT MODEL directly to produce interactive 3D documentation and experiences.

Use of the Virtual Product Mode with IoT and Digital Twins

Companies that produce complex products are embracing IoT and Digital Twins. Digital Twins are digital models of individual products – not just the product model, but each individual product (e.g. serial number). The Digital Twin includes the complete history of the product – not just its “as-built” configuration, but also its “as maintained” and “as serviced” configuration – all the way up to its current configuration.

And critically, the Digital Twin maintains a live connection to the actual product. This allows the Digital Twin to access the current state of the product: sensor reading, fault codes, etc. It enables real-time reporting of product status and fast diagnosis and correction of issues. For complex products, this flood of real-time data can be overwhelming.

The VIRTUAL PRODUCT MODEL can provide a visualization platform for the Digital Twin’s historical and real-time data. Visualizing the data in the context of the 3D model can make it easier to understand and to resolve any issues.

How to Implement a Virtual Product Model

To implement a VIRTUAL PRODUCT MODEL, you first need to identify your 3D data sources. What CAD formats are used internally? What about suppliers: are you able to get their CAD files?

If everything is in one CAD format, implementing a complete VIRTUAL PRODUCT MODEL will be that much easier.

The CAD system or the primary CAD system is a logical place to start. If other CAD formats are used, you may need to get those design files in an open format like IGES or STEP. The biggest challenge using a CAD system will be performance. If your models are big, it might not be possible to load them in a single instance. Your CAD vendor may supply a viewer that can handle the very large CAD files and multiple formats. Another alternative is to “dumb” down the models, removing features and decreasing accuracy but this can undermine the value of having the VIRTUAL PRODUCT MODEL.

Also, keep in mind it is not necessary to have a complete 3D VIRTUAL PRODUCT MODEL to start. Maybe you want to test the idea. You could use an incomplete model, but then the benefits of the VIRTUAL PRODUCT MODEL will be reduced.

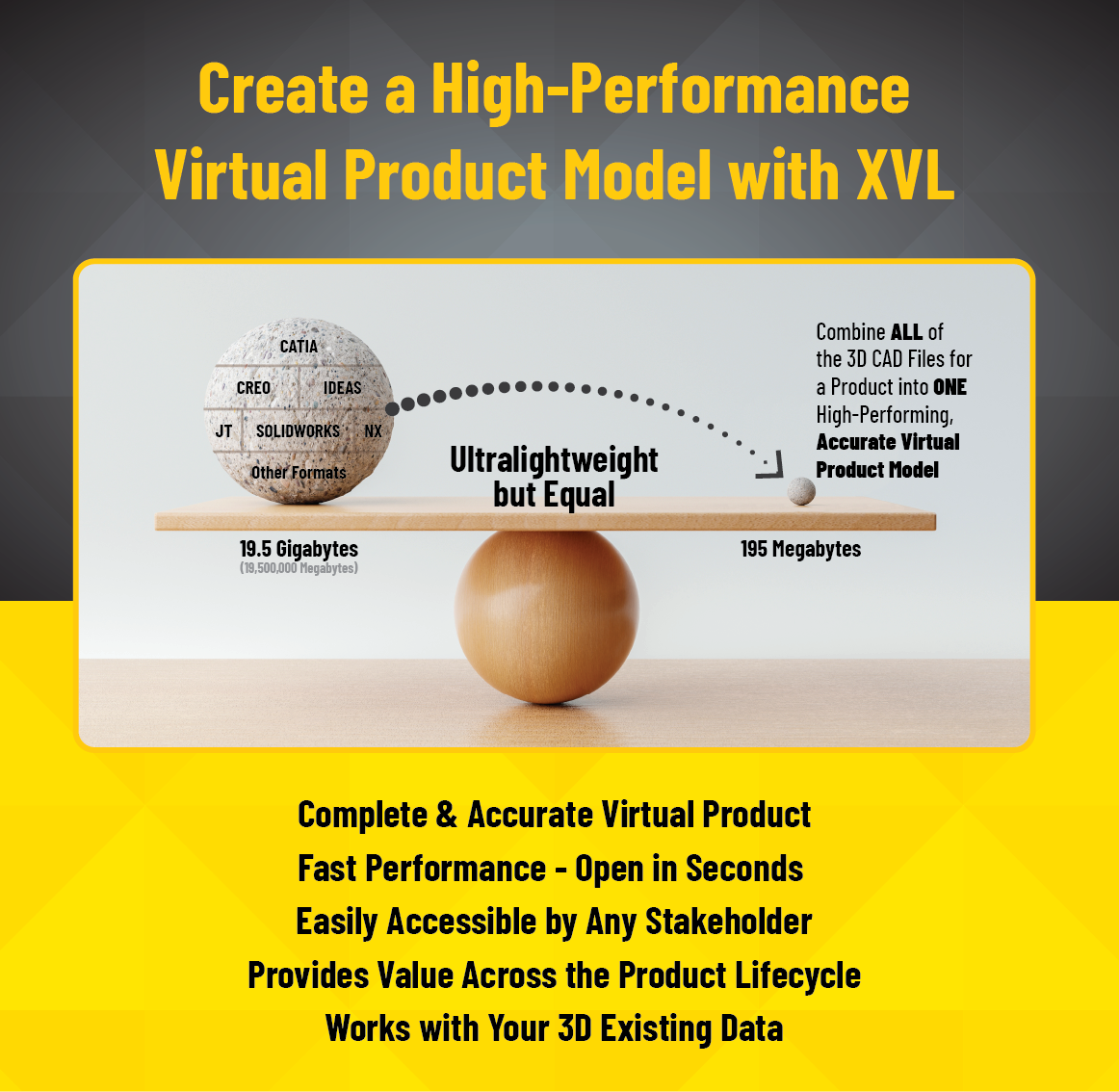

XVL: A Solution for Creating a Virtual Product Model

One solution to consider is XVL from Lattice Technology. XVL is an ultra-lightweight and highly accurate 3D format that can be used for implementing a VIRTUAL PRODUCT MODEL. It is CAD-agnostic and supports all major CAD and open formats. It is 1/100th the size of CAD data, yet it retains CAD-level accuracy. And because it is so lightweight it can be used on PC’s, laptops, tablets and even phones. Lattice Technology provides XVL-based VIRTUAL PRODUCT MODEL solutions for the use cases reviewed, and much more.

To Learn More - Download the 5-page XVL Whitepaper