Mitsubishi: Improving assembly processes using XVL

Planning and Validating the Assembly Processes Using XVL

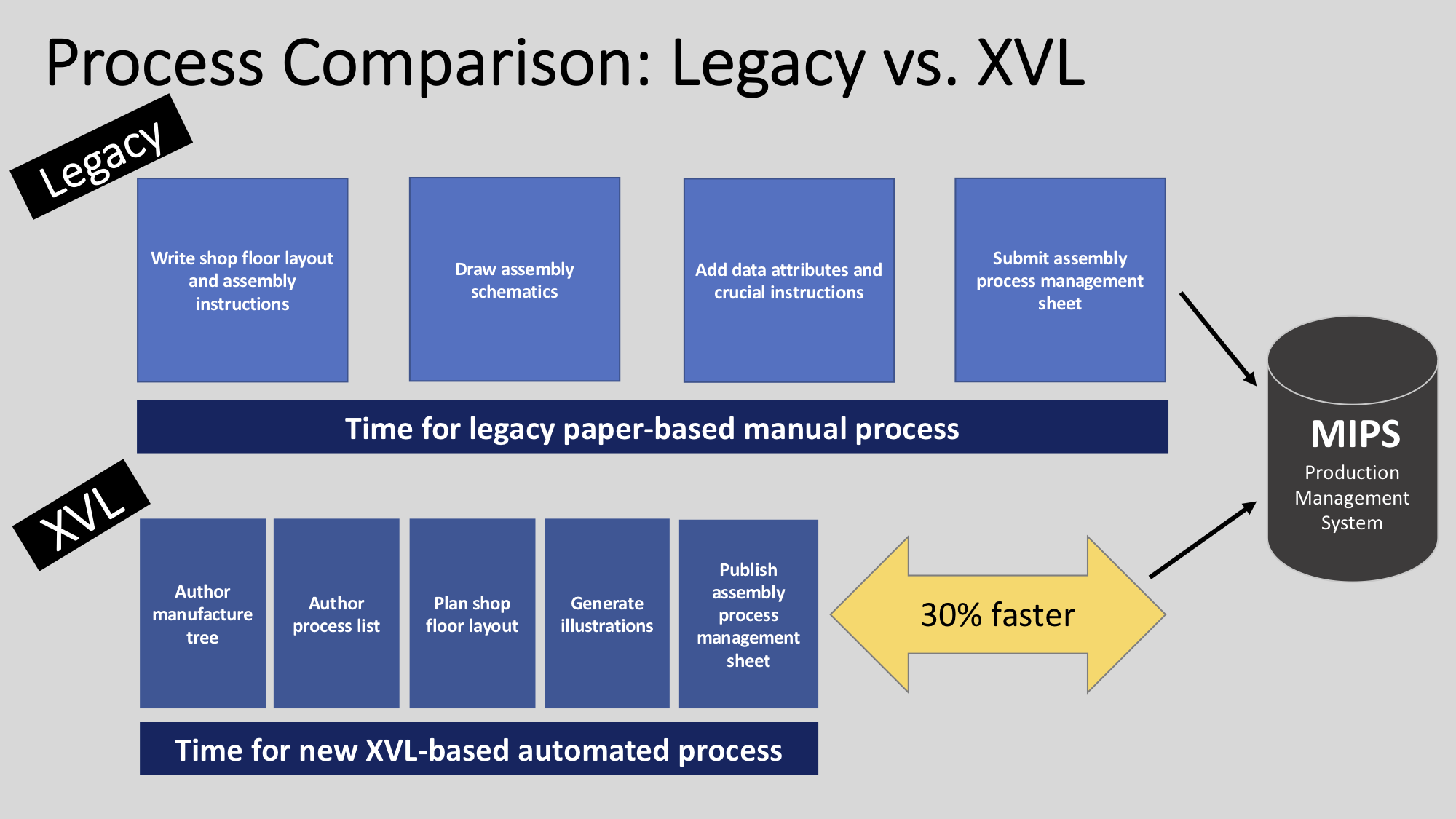

Mitsubishi Speeds Manufacturing Planning by 30%

When MAM introduced 3D into its product development, it was difficult to use downstream because the company was still deeply entrenched in delivering assembly process information using paper reports and drawings.

When MAM introduced 3D into its product development, it was difficult to use downstream because the company was still deeply entrenched in delivering assembly process information using paper reports and drawings.

The design, product planning and production divisions, which are responsible for manufacturing planning, continued to use the traditional 2D methods, long after 3D was introduced. This caused delays and frustrations. For example, the product planning division waited for delivery of approved hard copy drawings from the design division, and the production division then waited for the hard copy assembly process management sheet. This resulted in long delays as the work of manufacturing planning had to wait until they received each division’s paper instructions.

By using XVL, MAM was able to change from a paper-based process to an electronic-based process, resulting in shortened lead times and a reduction in inventory. The new process is known within the company as the “Flexible Manufacturing Method.”