Assembly Work Instructions

Assembly work instructions are an essential component of the manufacturing process. Without clear and concise instructions, assembling products can be a challenging and time-consuming task. 3D assembly instructions have become increasingly popular due to their ability to provide a visual guide to the assembly process. In this post, we'll explore the benefits of using 3D assembly instructions and how assembly instruction software can simplify the assembly process planning.

To properly perform manufacturing planning, in addition to having access to the complete product data (all parts and subassemblies), the manufacturing engineer should have virtual access to tools, tooling, jigs, fixtures, and even human models.

Benefits of 3D Assembly Instructions

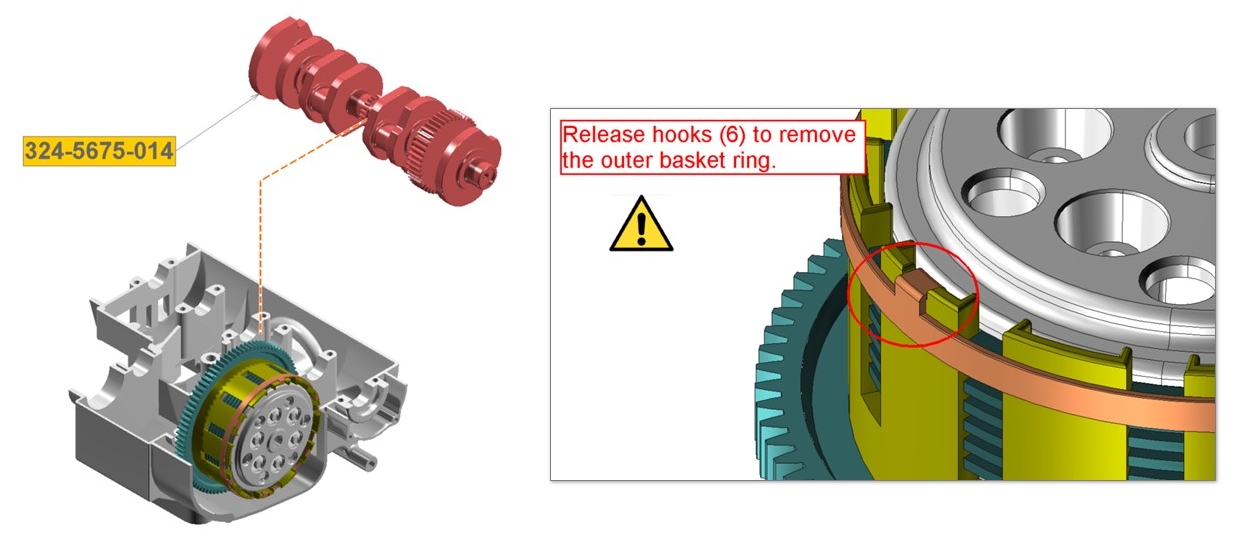

One of the significant advantages of using 3D assembly instructions is that they provide a visual representation of the assembly process. This visual guide allows for a better understanding of the process, making it easier to follow and reducing the likelihood of errors. With 3D assembly instructions, workers can easily see how each part fits together and understand the order in which to assemble them.

Another benefit of 3D assembly instructions is that they allow for more efficient assembly. With traditional paper instructions, workers may need to repeatedly reference the instructions as they work, slowing down the assembly process. With 3D assembly instructions, workers can simply refer to the visual guide, speeding up the assembly process and reducing the likelihood of errors.

Benefits of Assembly Instructions Software

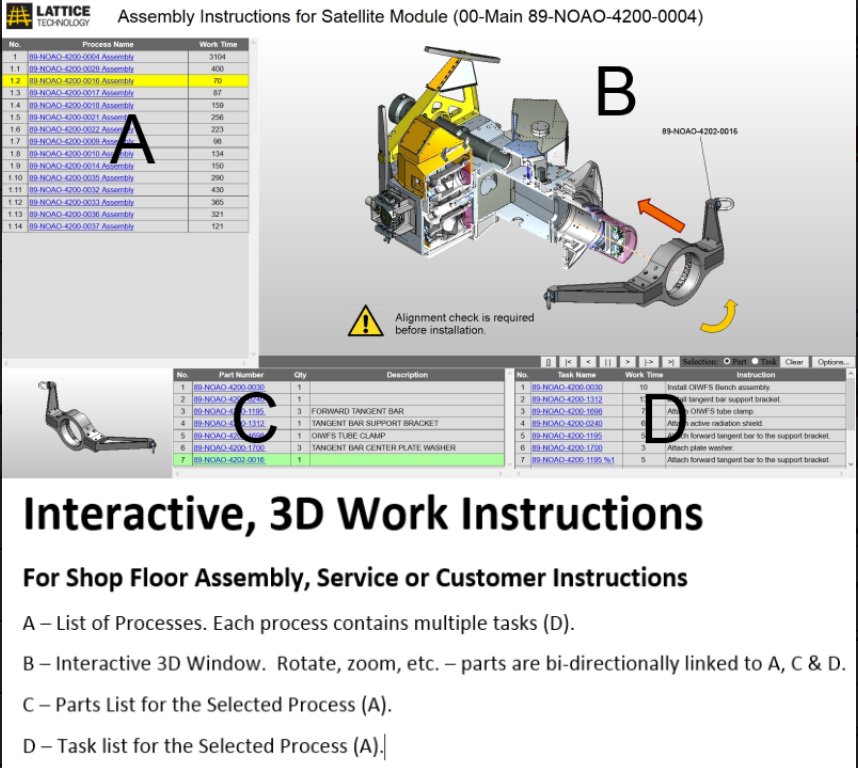

Assembly instructions software can simplify the assembly process planning. With the help of assembly instruction software, manufacturers can create assembly instructions quickly and easily. The software allows for the creation of clear and concise instructions, reducing the likelihood of errors and streamlining the assembly process.

Assembly instructions software can also help manufacturers save time and money. With traditional paper instructions, manufacturers may need to hire a technical writer to create the instructions. This process can be time-consuming and costly. Assembly instructions software eliminates the need for a technical writer, allowing manufacturers to create their instructions quickly and efficiently.

Assembly Process Planning Software for the Manufacturing Engineer

Manufacturing engineers can greatly benefit from the use of complete 3D models during their manufacturing assembly planning. With a complete 3D model, engineers can virtually access all parts and subassemblies, as well as the tools, tooling, jigs, fixtures, and human models needed for assembly. This allows them to create a highly detailed manufacturing plan that takes into account all aspects of the assembly process.

Software like XVL Studio brings all of this data together virtually for complete planning.

Assembly Process Planning with Software

By utilizing assembly instruction software, manufacturers can easily create clear and concise manufacturing work instructions, reducing the likelihood of errors and streamlining the assembly process.

These 3D assembly instructions provide a visual guide to the assembly process, allowing workers to see how each part fits together and understand the order in which to assemble them.

By incorporating these tools into the manufacturing process, manufacturers can improve efficiency, reduce errors, and ultimately increase productivity.

Learn More

Visit our Manufacturing Work Instructions solution page.

Have a question or want to start a conversation? Click here.