Enhanced Electronic Work Instructions - New Features - Blog

New features make XVL more powerful for Empowering Manufacturing Engineers to create robust

work instructions

In the realm of electronic work instructions, staying abreast of the latest advancements is crucial for manufacturing engineers seeking to optimize their processes. XVL Studio, a cutting-edge software tool, continues to push the boundaries of work instruction creation and management. In this blog post, we will explore three exciting new features of XVL Studio that are revolutionizing the manufacturing landscape: Auto-Update of Design Changes, Expanded Format Support, and Animated Highlighting with Trace Lines during Playback. Let's dive in and discover how these features can empower manufacturing engineers to achieve greater efficiency and precision.

Auto-Update of Design Changes

Auto-Update of Design Changes

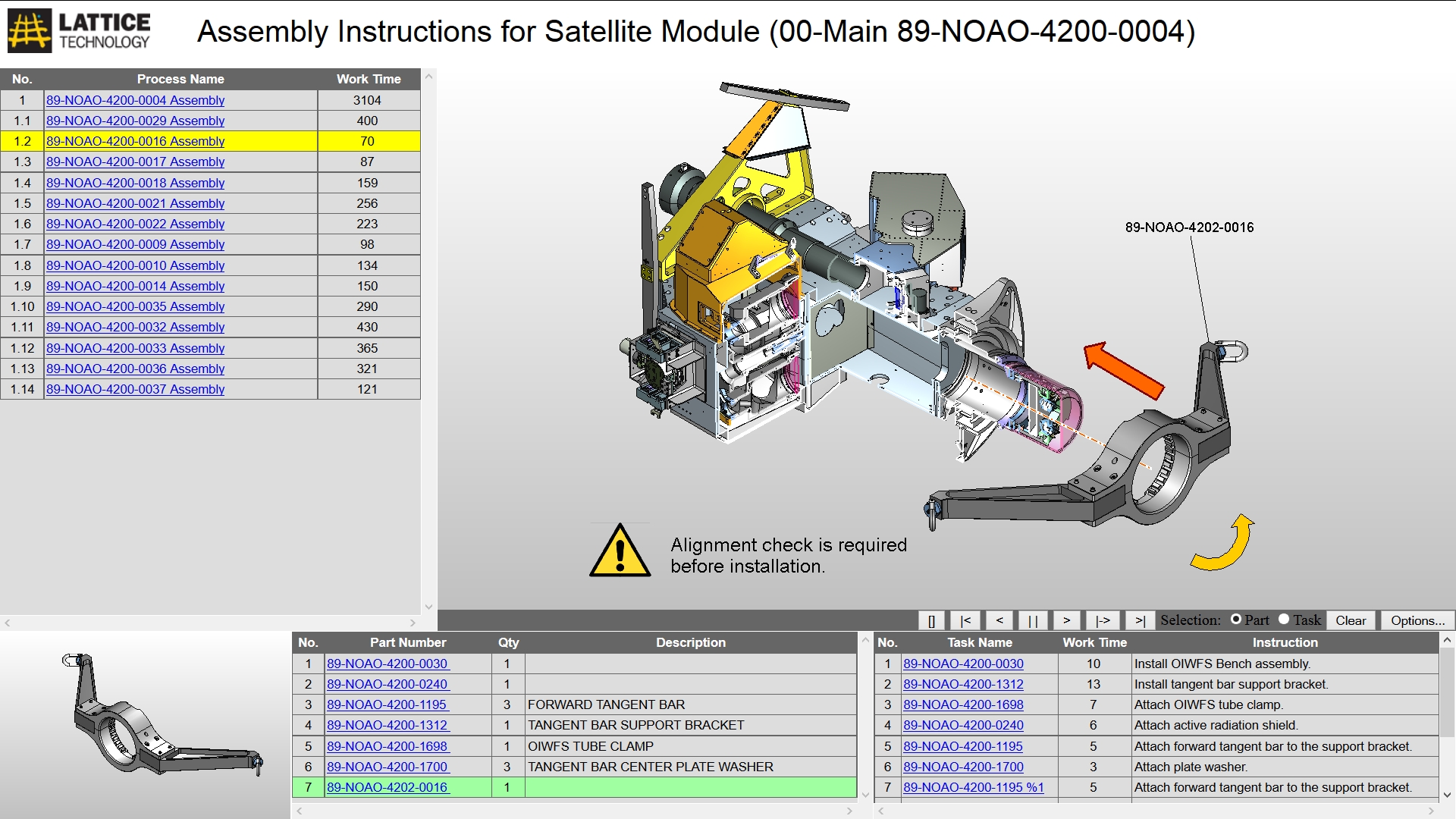

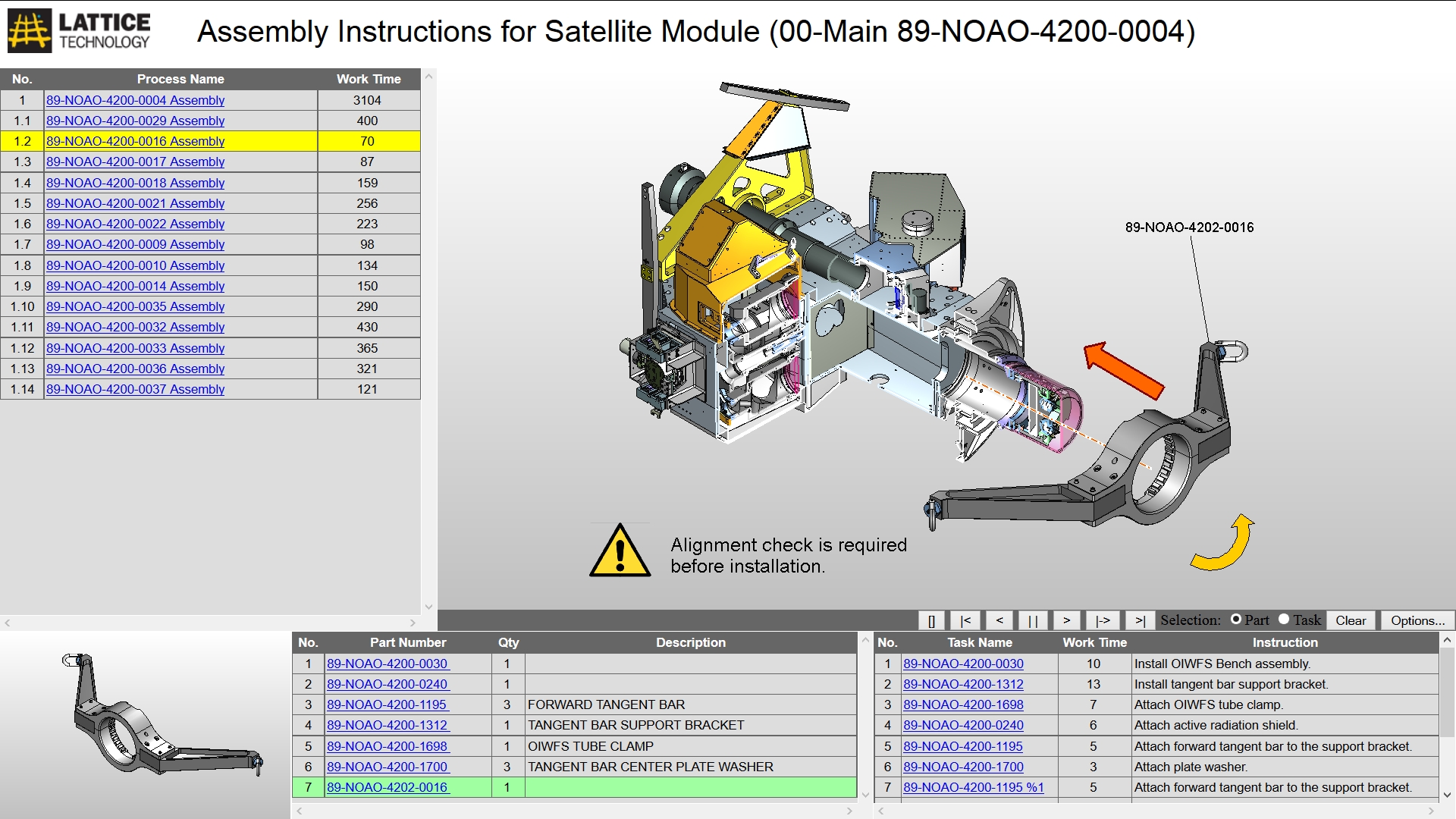

Gone are the days of manually updating work instructions when design changes occur. XVL Studio's "Auto Detect and Update" feature automatically scans the new version of the native 3D CAD model and identifies the changes from the previous version.

XVL Studio presents the changes to the user for verification, and once verified, applies all the work done on the old version to the new version. This feature not only saves time but also enables concurrent work, allowing manufacturing engineers to start their tasks earlier with the confidence that their work will be preserved when design changes occur.

Expanded Format Support and Templates

XVL Studio delivers flexibility when it comes to sharing work instructions. The latest version now supports Lattice Web3D joining formats that include Microsoft Excel, 2D PDF, and 3D PDF.

Additionally, the software offers powerful template functionality, enabling the creation of work instruction templates according to specific business standards and requirements of your business. With these templates, engineers can easily publish work instructions in multiple formats, significantly reducing authoring time. The automated process of inserting 3D models, processing the work instructions, and publishing the final document simplifies the entire workflow.

Animated Highlighting with Trace Lines during Playback

Visual clarity and guidance are paramount in work instructions, especially for complex assembly processes. XVL Studio's latest feature, Animated Highlighting with Trace Lines, takes visual communication to the next level. During the playback of work instructions, this feature dynamically highlights components and traces their movements using animated lines. By providing a clear visual path, operators can easily follow the instructions, minimizing errors and improving efficiency. The animated electronic work instructions can guide operators through intricate steps, eliminating any ambiguity that may arise during the assembly process.

Visual clarity and guidance are paramount in work instructions, especially for complex assembly processes. XVL Studio's latest feature, Animated Highlighting with Trace Lines, takes visual communication to the next level. During the playback of work instructions, this feature dynamically highlights components and traces their movements using animated lines. By providing a clear visual path, operators can easily follow the instructions, minimizing errors and improving efficiency. The animated electronic work instructions can guide operators through intricate steps, eliminating any ambiguity that may arise during the assembly process.

Conclusion

XVL Studio continues to evolve as a leading software tool for electronic work instructions, catering to the evolving needs of manufacturing engineers. The Auto-Update of Design Changes feature ensures that work instructions remain synchronized with the latest design revisions, reducing errors and saving time. The expanded format support, including Excel, 3D PDF, and Web3D, enables seamless collaboration and distribution with any stakeholder. Lastly, the Animated Highlighting with Trace Lines feature enhances visual guidance, enabling operators to easily follow complex assembly procedures.

By leveraging these new features of XVL Studio, manufacturing engineers can streamline their work instruction creation and management processes, resulting in increased productivity, improved accuracy, and enhanced collaboration. Embrace the power of XVL Studio's new features and propel your manufacturing operations to new heights of efficiency and success.