Using XVL for Detailed Assembly Planning

Manufacturers traditionally begin their Assembly Process Validation after the CAD design is completed, and a prototype is being generated.

There is a better way. With XVL, learn how you can easily perform design reviews on your complete product, combining all CAD files together for complete reviews. And XVL is designed to be easy-to-use so that you can engage non-technical stakeholders.

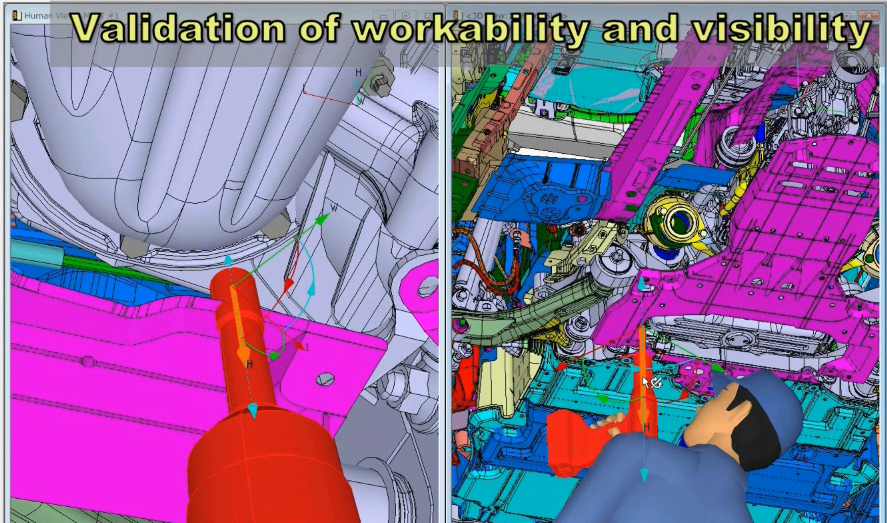

Watch this video to see how humans can be modeled into the process as well as their tools.

You will see two views:

- On the left, is the view the person would see

- On the right, is the view of the person performing the work for perspective

Simulate Your Assembly or Service Process using XVL

- Using the Lattice solution, Assembly Process Validation (APV) can be performed early, when issues are easy and inexpensive to fix - right when the initial CAD design is released.

- There is no need to wait for the final design release

- Starting the process early reduces the need for physical prototypes.

- Validate the entire assembly process using design data

- Instead of performing APV on portions of your design, Lattice enables manufacturers to validate using the entire 3D model.

- Validate the entire model without splitting it into subassemblies

- It is more efficient, as only one validation check is needed

- Validating against all parts at once eliminates the possibility of missing issues that were left out of the initial check

- Manufacturers can also track issues as the design changes

- Forward validation results from previous models into new versions

- Easily check assembly issues when the design updates

- The Lattice APV solution allows manufacturers to use a variety of validation features, including human models, tools, and fixtures.

- Human mannequins check safety and workability

- Add tools and fixtures to check the feasibility

- Visualize processes and full-scale models in VR

- Users can generate issue reports directly from their 3D models

- Record any scene in 3D, add annotations and markups

- Include 2D or 3D data

Tool Clearance

How often have you found yourself frustrated while working on something, like your car, wondering why a company would design a product that's so difficult to service? For example, maybe you can't fit a wrench into the required space.

With XVL from Lattice Technology, these issues can be easily simulated and addressed during the design phase to ensure your products are easy to work on.

The video below demonstrates how the wrench's swing is visualized, showing its range of motion and identifying when it collides with other components. While this is a simple example, it effectively highlights the power of XVL in preventing such design challenges.

Learn More

Click the button below to request that someone from our team contact you to discuss your manufacturing challenges.