Digital Transformation: What is the Best 1st Step?

We are in the business of helping make manufacturing companies be more efficient, increase quality, and be more profitable.

In this blog post, we will explore 8 opportunities manufacturers should consider within the realm of digital transformation.

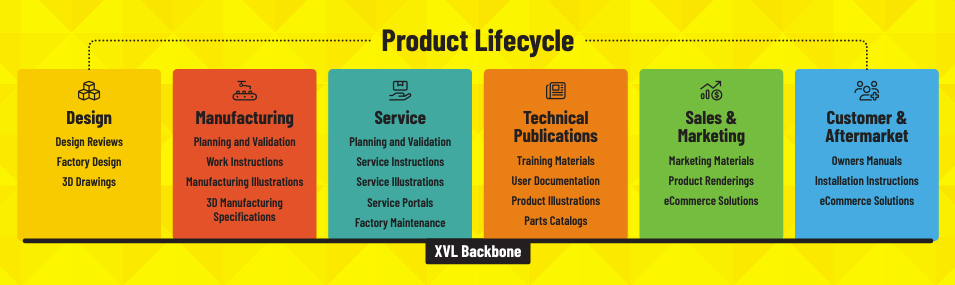

Scope: Design to Customers

Effectively using your 3D model data across your company and even to customers is the starting place for Digital Transformation. Learn how XVL from Lattice Technology can help you do this!

Manufacturing planners should consider enhancing accessibility, collaborating with stakeholders, gathering input for design, and optimizing various processes throughout the manufacturing lifecycle; from design to customer service. Having a unified method for sharing data within the manufacturing company and even with customers will have dramatic impacts on productivity, quality, and profit.

Foundational

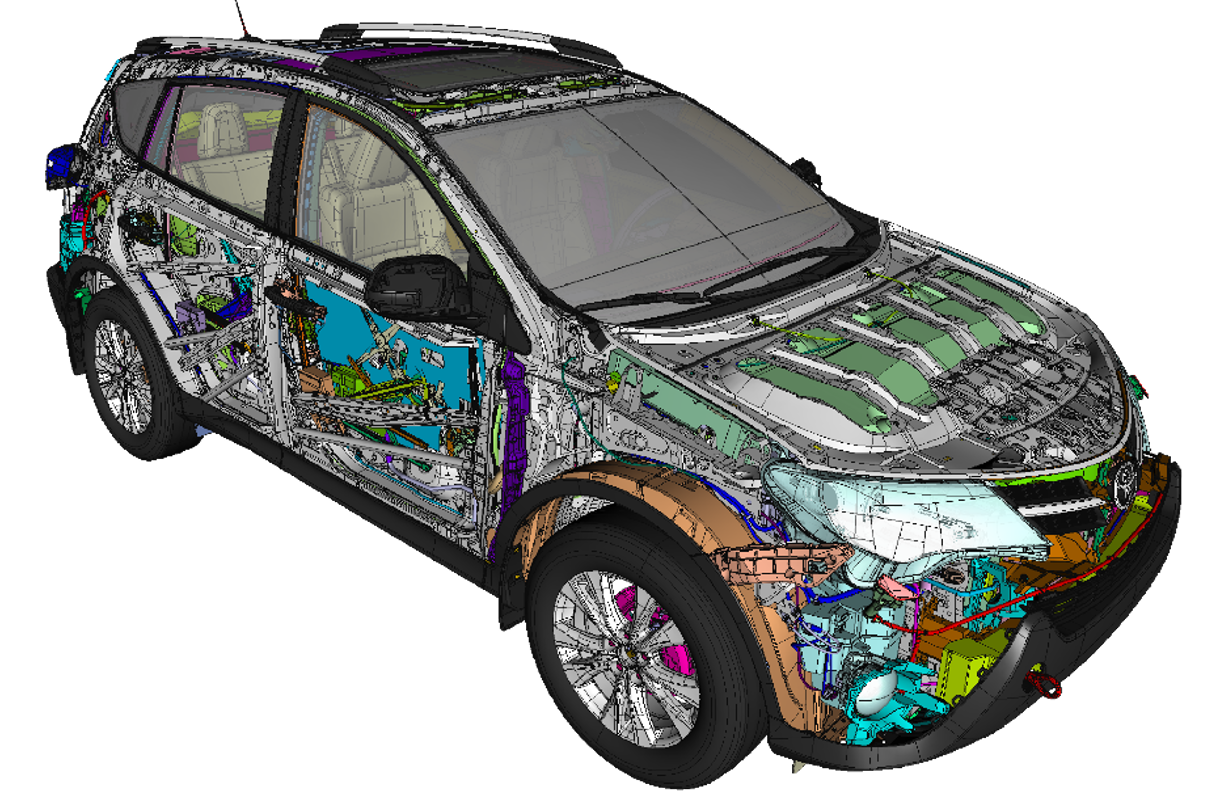

We call it the Virtual Product Model. The Virtual Product Model, contains all of the parts for the entire finished product, combining all of the 3D CAD files used in product design, regardless of their format.

And it maintains CAD-level precision.

With this Virtual Product Model, any stakeholder who needs complete design data for the entire product can easily access it. (Image courtesy of the Toyota Motor Corporation).

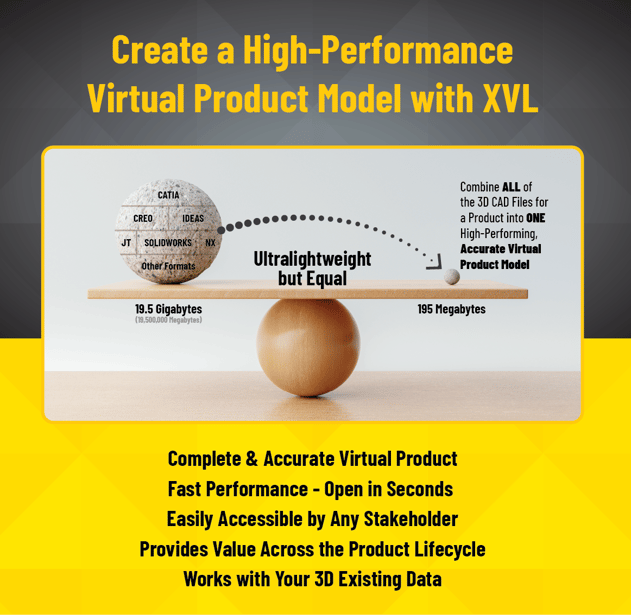

Performance

The first problem is usually performance. When CAD files get too large, it can be impossible to combine all of the parts into a single file and open it.

With XVL, native 3D CAD files are reduced to about 1/100th of their original size.

Usability

The second problem is usability. Non-CAD users need to be able to access this information with standard devices and without expensive licenses and advanced expertise.

With XVL, many consumption options are available, and all are FREE to consumers. Access options even include AR and VR.

What Makes XVL Unique

- Supports All Major 3D CAD Formats: All 3D CAD Files can be Combined into a Single Virtual Product

- Accurate: XVL Maintains CAD-level Precision for Real Work

- Lightweight: About 1/100th the Size of the Original CAD, e.g. 19.5 gigabytes (19,500 megabytes) to 195 megabytes

- Processes Net Changes between CAD Versions: Very Important for Preserving Work when Engineering Change Orders (ECOs) occur

- Consumption: Many Options for Stakeholders - ALL FREE

8 Opportunities for the Manufacturing Company Embarking on Digitial Transformation

1) Sharing with Stakeholders: Building a Collaborative Ecosystem

Effective communication with stakeholders is vital for successful manufacturing planning. Utilizing collaborative platforms facilitates seamless information sharing among different departments, ensuring everyone involved is on the same page. This leads to better decision-making and improved overall efficiency.

With XVL, all stakeholders can easily access the Virtual Product Model for FREE with many options.

2) Gather Input for Design: Informed Decision-Making

Designers should actively seek input from various stakeholders during the design phase. Engaging with design teams, production teams, and other stakeholders provides valuable insights.

Gathering input during design is crucial; everyone knows that. Effectively engaging stakeholders is difficult, but not with XVL.

3) Assembly Planning: Precision in Execution

Precision in assembly planning is essential for achieving optimal manufacturing outcomes. Leveraging advanced assembly planning tools ensures the assembly process is efficient, error-free, and aligned with design specifications. This step is critical for maintaining product quality and reducing production costs.

With XVL, the entire assembly process can be created virtually, part by part, while building the Manufacturing BOM (mBOM) at the same time.

4) Virtually Test the Assembly Process: Optimizing Before Physical Execution

Can you simulate your manufacturing process? Simulation tools provide the ability to model and simulate manufacturing processes. By identifying potential bottlenecks and errors in a virtual environment, manufacturing planners can optimize workflows, reduce downtime, and improve overall operational efficiency. This approach minimizes errors, accelerates time-to-market, and enhances overall efficiency by addressing potential issues in a virtual environment.

With XVL, the complete assembly plan can be virtually simulated. Is there human access? Is it ergonomic? Will the tool or robotic arm fit? How can we optimize the process? All of this can be done with XVL.

5) Assembly Work Instructions: Clarity in Execution

Clear and comprehensive work instructions are vital for smooth execution on the assembly floor. Manufacturing planners should invest in creating detailed digital work instructions that guide operators step-by-step through the manufacturing process. This reduces errors and enhances the overall efficiency of the assembly line.

With XVL, the same Virtual Product Model and the assembly plan can be used to create interactive work instructions. These work instructions include links to the Bill of Materials and Process Steps.

6) Tech Pubs: Leveraging Technology for Documentation

Tech Pubs play a crucial role in disseminating information effectively. Clear and concise documentation enhances understanding and contributes to the overall success of the manufacturing process.

With XVL, Tech Pubs can work with the Virtual Product Model directly to quickly and accurately produce whatever documents they need. And they can start work earlier because XVL stays connected to the original CAD, so if an ECO occurs, their work is preserved, and they only need to be concerned with the changes.

7) Customer Service: Meeting Customer Expectations

The scope of Digital Transformation reaches to your Customer Service Department and even customer self-service. For instance, identifying replacement parts.

With XVL, the Virtual Product is used for replacement part identification and can even be used to create a parts ordering system. And can also include instructions for assembly.

8) Service Instructions: Enabling Effective Maintenance & Repair

This is similar to creating Assembly Work Instructions. Whether your company performs this function or it is performed by dealers, other third parties, or even by customers, it is important. Accessible and detailed service instructions contribute to faster repairs, reduced downtime, and increased equipment lifespan, benefiting both customers and the manufacturing organization.

With XVL, detailed instructions can be created from the Virtual Product.

Learn More

These 8 considerations are just some ways a manufacturing company can embrace Digital Transformation.

Which of these resonates with you and you would like to learn more about? Visit the page below to submit your question.