Beyond the 2D Mindset: Overcoming Barriers to Model-Based Manufacturing

Beyond the 2D Mindset: Overcoming Barriers to Model-Based Manufacturing

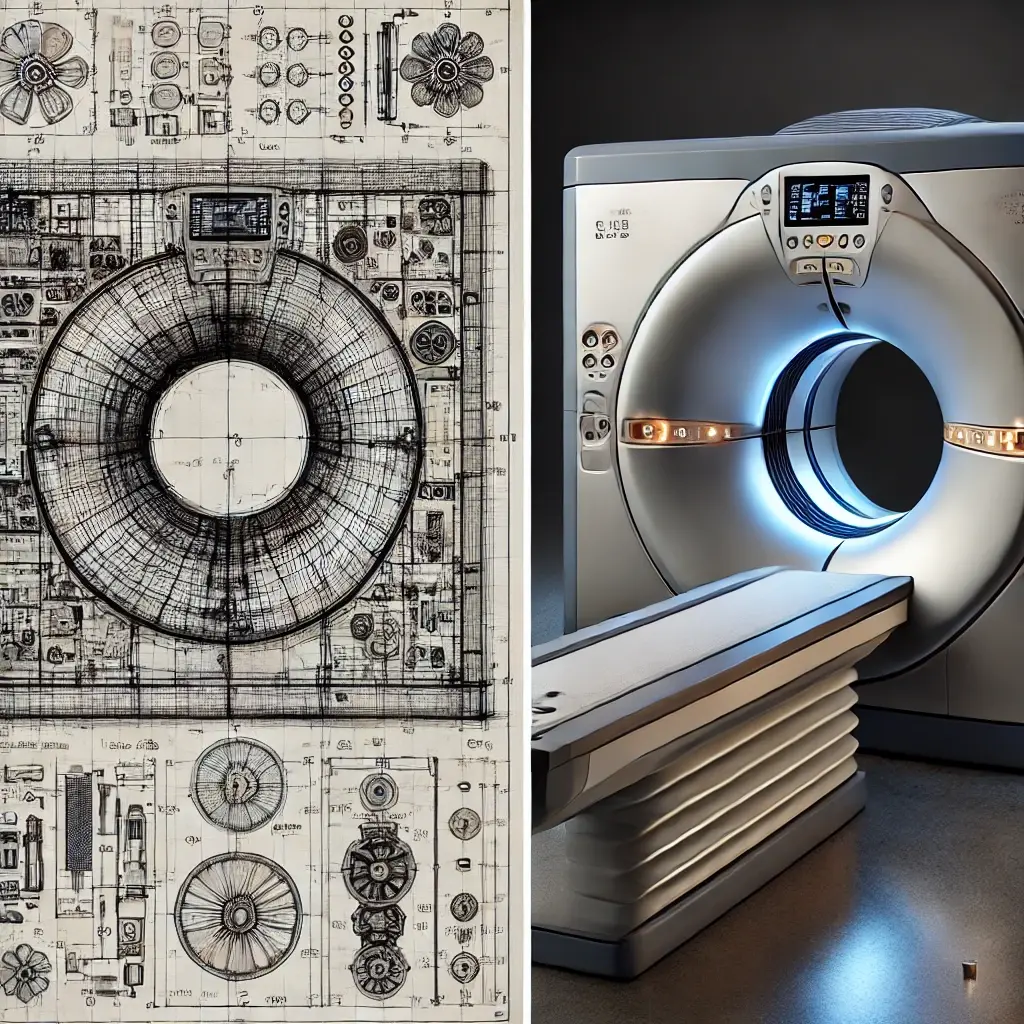

For manufacturing planners, efficiency and precision are everything. However, many production workflows still rely on traditional 2D drawings, despite the promise of Model-Based Definition (MBD). The idea of fully digital, annotated 3D models is compelling—reducing ambiguity, streamlining processes, and improving data consistency. Yet, widespread MBD adoption remains a challenge.

Why? Because manufacturing planners don’t just need design data—they need a practical, reliable, and accessible format that works across teams, suppliers, and shop floors. While CAD systems like SOLIDWORKS, PTC Creo, Autodesk Inventor, and CATIA support MBD, many companies struggle with real-world implementation.

Challenges in Adopting MBD in Manufacturing Planning

- Resistance to Change Legacy workflows are deeply ingrained. Engineers, suppliers, and shop floor workers are accustomed to 2D drawings, which provide a single-glance reference without the need for interactive navigation. Transitioning to MBD requires training, process adjustments, and cultural shifts—all of which take time.

- Lack of Standardization Unlike traditional 2D drawings, which follow well-defined industry standards (ASME, ISO), MBD lacks universal conventions for dimensioning, tolerancing, and annotation placement. Without strict consistency, misinterpretation can occur, slowing down production rather than streamlining it.

- Software Limitations and Interoperability Issues While CAD systems are evolving, not all MBD implementations are created equal. Differences in SOLIDWORKS, PTC Creo, Inventor, and CATIA mean that annotations, dimensions, and PMI (Product Manufacturing Information) are not always displayed consistently across platforms. Interoperability challenges between suppliers can create bottlenecks, forcing workarounds or continued reliance on 2D exports.

- Supplier Compatibility Many manufacturers work with external vendors who still require 2D deliverables, such as DXF files for CNC cutting or PDF prints for inspections. If a supplier can’t fully utilize MBD, then manufacturing planners must maintain parallel workflows, negating some of MBD’s efficiency gains.

- Managing Legacy 2D Data

For many companies, decades of 2D drawings represent a massive investment. Converting thousands of documents into MBD is impractical. A hybrid approach—where new designs adopt MBD but legacy drawings remain unchanged—creates additional complexity in managing two systems.

How XVL Solves These Challenges

Instead of forcing an all-or-nothing shift to MBD, XVL provides a pragmatic solution:

✅ Consolidates All CAD Formats – XVL integrates models from SOLIDWORKS, PTC Creo, Inventor, CATIA and others, preserving PMI and annotations while standardizing the experience across different CAD ecosystems.

✅ Lightweight, Accessible Digital Twin – Unlike native CAD files, XVL reduces file size by 99% without losing precision. Manufacturing planners can review large assemblies effortlessly on any device—without requiring expensive CAD software.

✅ Seamless Transition from 2D to 3D – XVL doesn’t demand a disruptive, immediate switch. It allows companies to repurpose existing 2D data while gradually transitioning to an interactive 3D digital twin that integrates PMI and work instructions.

✅ Streamlined Collaboration – Because XVL is vendor-neutral, manufacturing planners can share files across teams and suppliers without compatibility concerns, ensuring consistency in annotations, dimensions, and production details.

Unlocking the Future of Manufacturing Planning

MBD adoption is not just about eliminating drawings—it’s about creating a smarter, more efficient manufacturing process. XVL enables manufacturing planners to optimize workflows, improve collaboration, and enhance quality control without disrupting existing operations.

With XVL, the transition from static 2D drawings to dynamic 3D manufacturing is no longer an obstacle—it’s an opportunity.

Are you ready to streamline your manufacturing planning with XVL?

Do you want to brainstorm ideas for your company? Click below and someone from our team will reach out to you.