Maximize Manufacturing Productivity: 5 Benefits of Bill of Material Management with XVL

In today's fast-paced manufacturing landscape, efficiency is paramount. Every aspect of the production process needs to be optimized to ensure not only timely delivery but also high-quality output. One area where optimization can yield significant benefits is Bill of Material (BOM) management.

Benefits of XVL in BOM Management:

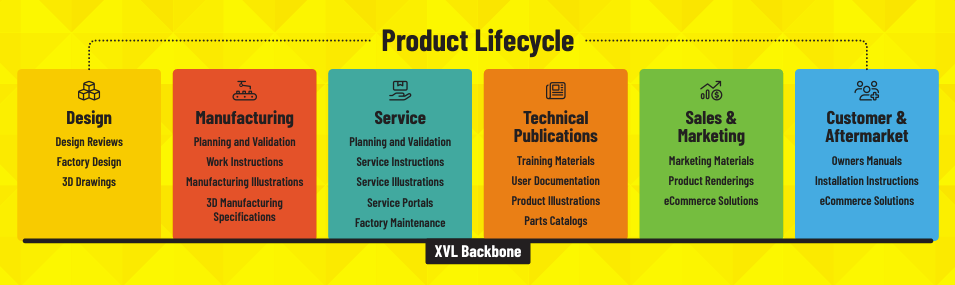

All BOMs originate from the eBOM in the 3D CAD system/s. XVL leverages the eBOM (regardless of CAD vendor) to all other BOMs a manufacturing organization might need, including the Manufacturing BOM (mBOM) and the Service BOM (sBOM). These related BOMs can be used across the product lifecycle.

1. Efficient Data Exchange: XVL facilitates seamless data exchange between different departments and stakeholders involved in the manufacturing process. Whether it's designers, engineers, or production managers, everyone can access and collaborate on the same up-to-date BOM data without worrying about compatibility issues.

2. Accurate Visualization: With XVL, manufacturers can visualize BOMs in 3D with exceptional clarity and detail. This allows for better comprehension of complex assemblies, helping to identify potential issues early in the design phase and streamline production processes.

3. Enhanced Collaboration: Collaboration is key to success in manufacturing, and XVL fosters collaboration like never before. Teams can annotate 3D models directly, communicate ideas more effectively, and make informed decisions collaboratively, leading to faster problem-solving and improved overall productivity.

4. Streamlined Documentation: Generating documentation such as assembly instructions, maintenance manuals, and part catalogs is simplified with XVL. By leveraging the accurate 3D representations provided by XVL, manufacturers can create comprehensive documentation that is easy to understand and follow, reducing errors and rework on the shop floor.

5. Agile Response to Changes: In the fast-paced world of manufacturing, change is inevitable. XVL equips manufacturers with the agility to respond swiftly to changes in design, production requirements, or customer preferences. Whether its updating BOMs, revising assembly processes, or accommodating design modifications, XVL ensures that changes are implemented seamlessly across the organization.

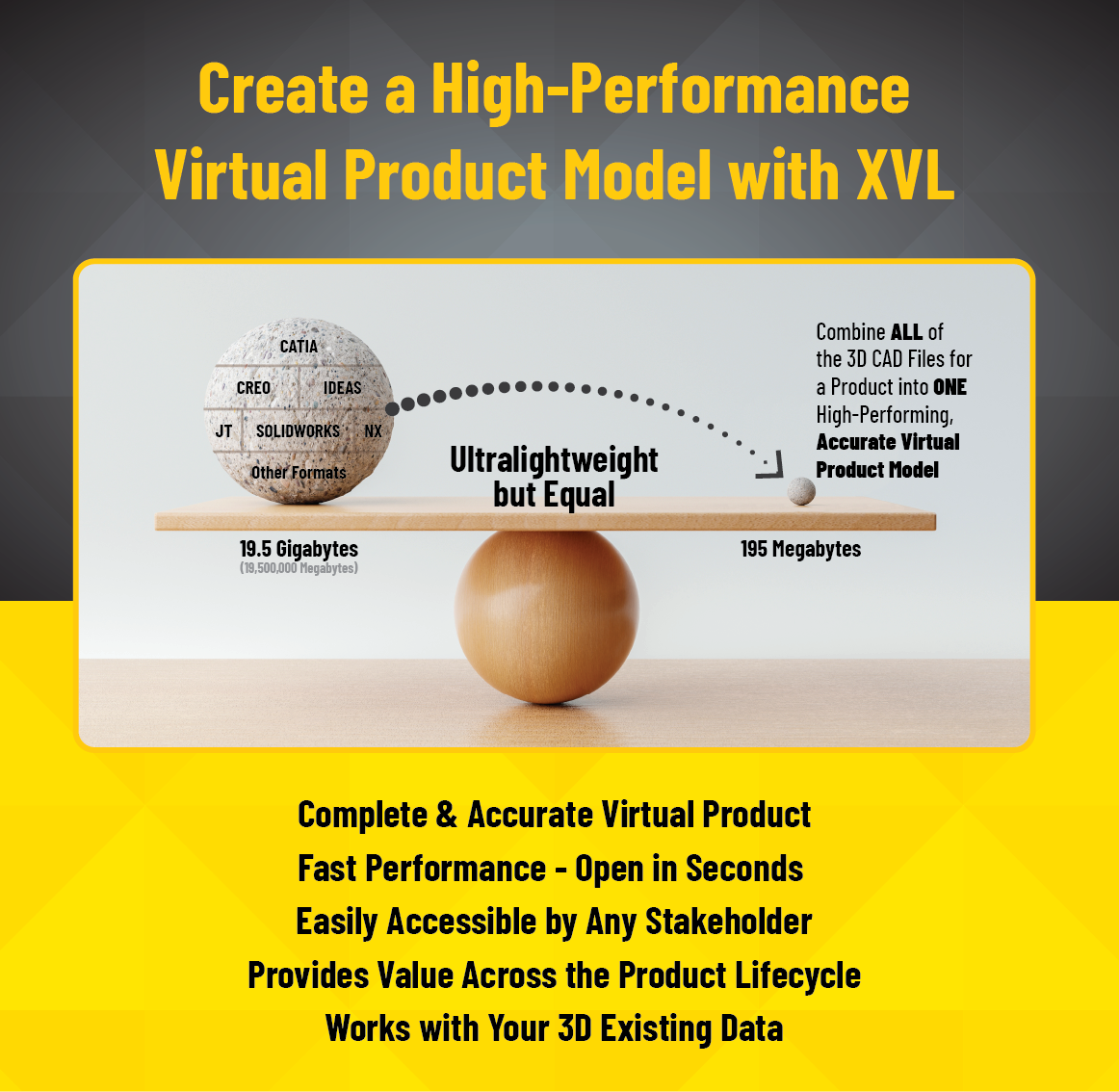

What is XVL?

XVL is a lightweight, highly compressed format optimized for 3D data. It allows for the accurate representation of complex 3D models, animations, and other graphical data in a fraction of the file size compared to traditional formats. Developed by Lattice Technology, XVL has revolutionized how manufacturers handle product data throughout the product lifecycle.

Conclusion:

In conclusion, the benefits of leveraging XVL for BOM management are clear: increased efficiency, enhanced collaboration, streamlined processes, and improved product quality. By harnessing the power of XVL, manufacturers can maximize productivity across the entire manufacturing lifecycle, from design to production to aftermarket support. In an increasingly competitive market, embracing innovative technologies like XVL is not just an option but a necessity for staying ahead of the curve.