JMU: XVL Digital Manufacturing Initiative Improves Processes

Japan Marine United needed a more intuitive way, that was cost-effective, for their workers to understand their complex assembly processes that could also accommodate their extremely large models

Japan Marine United (JMU), which was created in January 2013 by the merger of IHI Marine United and Universal Shipbuilding, is the 2nd largest shipbuilding company in the world. JMU manufactures a wide variety of vessels including supertankers, container ships, car ferries and military ships.

Situation

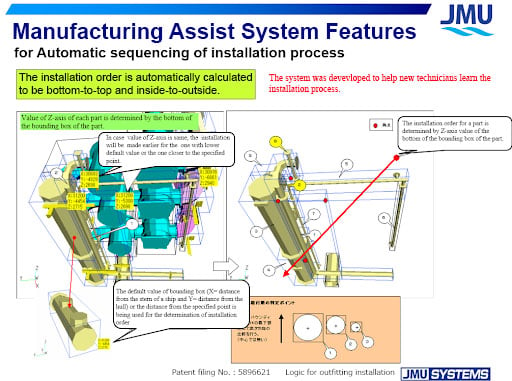

Faced with increasing global competition and experienced workers retiring, they launched a Digital Manufacturing (DM) initiative to improve their manufacturing processes. The centerpiece of their DM effort was the development of a “Next Generation Manufacturing Assist System for Outfitting (MAS)” based on XVL from Lattice Technology.

“Outfitting” means to install equipment to the hull. According to JMU’s Mr. Nakamoto, there was concern about outfitting inefficiency as far back as 2007. “Many skilled workers were retiring and were being replaced by new workers who didn’t have the same level of experience and knowledge. This generated concern about causing inefficiency in the installation work. This was the trigger for JMU to undertake the development of MAS in order to address these problems and to seek further reductions in manufacturing time.”

Mr. Nakamoto’s vision was inspired by the assembly instructions for hobby models, which are very easy to understand. Traditional manufacturing assembly instructions require very high levels of skill and a lot of time for the workers to understand the very complex drawings to prepare for the installation work. Mr. Nakamoto aimed to develop a system that allows workers to visualize the parts and the installation order intuitively, and to easily recognize the before and after configurations like the hobby model assembly instructions.

Solution

JMU chose XVL for their new MAS. First, they convert the 3D CAD design data to XVL, then use XVL Studio to create a process tree and author work instructions. They have even started making their own enhancements, such as automatically generating the installation process from the data, automatically adding the mounting dimensions for parts and equipment and validating the installation process using animation.

Read the complete JMU Use Case by clicking below.